Introduction: The Evolution of Titanium in Modern Watchmaking

Titanium stands as one of horology’s most fascinating materials – a silvery-gray metal that has transformed from an aerospace curiosity to a premium watchmaking staple. This remarkable element (atomic number 22 on the periodic table) offers an exceptional combination of properties that watchmakers increasingly prize for crafting exceptional timepieces.

Originally developed for aerospace and medical applications where its unique properties made it invaluable, titanium has made a remarkable transition into the world of fine watches. The material’s journey from specialized industrial applications to adorning our wrists represents one of the most significant material innovations in modern history of dive watch engineering.

What has driven this shift toward titanium in quality timepieces? As watch enthusiasts and manufacturers alike discover the material’s extraordinary qualities, titanium has evolved from a niche selection to a sought-after option in titanium watches and their development. Its lightweight nature, impressive strength, corrosion resistance, and hypoallergenic properties make it exceptionally well-suited for daily wear on the wrist.

As we explore deeper into titanium’s role in watchmaking, we’ll uncover precisely why this remarkable metal has become such a compelling choice for discerning watch enthusiasts and manufacturers alike.

The Fundamental Properties of Titanium for Watches

Before diving into titanium’s benefits for watchmaking, it’s important to understand the fundamental properties that make this metal so special. Titanium possesses a unique set of physical and chemical characteristics that differentiate it from other common watchmaking materials.

Key properties of titanium include:

- Low density: With a specific gravity of 4.5 g/cm³ (compared to stainless steel’s 7.9 g/cm³), titanium is significantly lighter while maintaining structural integrity

- High melting point: At 3,034°F (1,668°C), titanium maintains stability across extreme temperatures

- Naturally forming oxide layer: When exposed to oxygen, titanium develops a protective titanium dioxide (TiO₂) layer that provides corrosion resistance

- Non-magnetic properties: Unlike many metals, titanium remains non-magnetic, an important consideration for mechanical watches

- Excellent strength-to-weight ratio: Despite its lightweight nature, titanium offers comparable or superior strength to many steels

As a transition metal, titanium exhibits properties between those of light aluminum and dense steel, creating an ideal balance for titanium’s material properties and benefits. These inherent characteristics make it particularly well-suited for the demanding requirements of fine watchmaking.

For those interested in experiencing these properties firsthand, exploring titanium automatic watches reveals how these technical attributes translate into exceptional timepieces that combine functionality with comfort.

Unmatched Lightweight Comfort: The Primary Advantage

Perhaps the most immediately noticeable advantage of titanium in watchmaking is its remarkable lightness. Titanium watches typically weigh 40-60% less than their identical stainless steel counterparts, creating a wearing experience that many describe as transformative.

This significant weight reduction translates directly to enhanced comfort during extended wear. A typical 42mm titanium watch might weigh approximately 3 ounces (85 grams) compared to 5.3 ounces (150 grams) for an equivalent stainless steel model. This difference becomes especially apparent during active use or when wearing the watch for extended periods.

The psychological impact of this lightness shouldn’t be underestimated. Many titanium watch owners report “forgetting” they’re wearing a timepiece – a testament to the material’s comfort. This quality makes titanium watches particularly suitable for those with active lifestyles or professionals who wear their watches throughout long workdays.

The lightweight nature also allows for larger case designs without the typical weight penalty, enabling the creation of titanium watches that combine lightness with strength in ways previously impossible with traditional watchmaking materials. For those accustomed to the heft of stainless steel, the initial lightness of titanium can be surprising, but many quickly come to appreciate this defining characteristic.

Exceptional Strength-to-Weight Ratio

While titanium’s lightness is immediately apparent, its impressive strength might not be obvious until you understand its remarkable strength-to-weight ratio. This property describes how much force a material can withstand relative to its weight – and titanium excels in this category.

Despite being nearly half the weight of stainless steel, titanium offers comparable or even superior tensile strength. Titanium’s tensile strength (approximately 63,000 psi or 434 MPa) allows watchmakers to create cases that resist deformation while maintaining structural integrity under stress.

This strength-to-weight advantage means titanium watches can withstand impacts and daily wear without compromising on comfort. For active individuals, this combination proves particularly valuable – offering durability without the weight burden of traditional materials.

Many consumers incorrectly assume that a lighter watch must be less durable. In reality, the opposite is often true with titanium timepieces. The material’s strength ensures that rugged automatic watches can be designed to withstand challenging conditions while remaining comfortable enough for extended wear.

For watchmakers, this property allows for innovative designs that balance structural requirements with wearability – creating timepieces that offer the best of both worlds.

Superior Corrosion Resistance for Longevity

Titanium’s exceptional corrosion resistance represents another significant advantage for watchmaking. The metal forms a natural, self-healing titanium dioxide (TiO₂) layer when exposed to oxygen – creating a protective barrier that shields the underlying metal from environmental threats.

This passive oxide layer provides remarkable resistance to:

* Saltwater and ocean environments

* Human perspiration and body oils

* Chlorinated water (swimming pools)

* Various chemicals and substances encountered in daily life

Unlike stainless steel, which can corrode in harsh environments despite its “stainless” designation, titanium maintains its integrity even in challenging conditions. This property makes titanium particularly valuable for professional-spec dive watches and timepieces designed for marine environments.

The corrosion resistance extends beyond environmental factors to include galvanic compatibility – meaning titanium generally doesn’t react negatively when in contact with other metals. This property contributes to the long-term durability of titanium watches, helping them maintain their appearance and structural integrity over years of use.

For watch owners, this translates to peace of mind when wearing their timepiece in diverse environments – from ocean dives to everyday exposure to sweat and water.

Hypoallergenic Properties for Sensitive Skin

For approximately 10-15% of the population with metal sensitivities, titanium watches offer a significant advantage – they’re hypoallergenic. Unlike stainless steel, which typically contains nickel (the most common metal allergen), pure titanium and many of its alloys are biocompatible and extremely unlikely to cause skin reactions.

Titanium’s biological inertness – the same property that makes it suitable for medical implants – ensures that it doesn’t react with human tissue or cause irritation even with prolonged skin contact. This quality is particularly valuable for a watch, which maintains consistent contact with the skin throughout the day.

For those who’ve experienced redness, irritation, or rashes from traditional watch materials, titanium provides a welcome solution. The metal’s non-reactive nature ensures comfort even for those with the most sensitive skin or specific nickel allergies.

This hypoallergenic quality represents a significant but often overlooked advantage of titanium watches – allowing more people to enjoy fine timepieces without compromising on comfort or risking adverse skin reactions.

Thermal Properties: Enhanced Temperature Comfort

Titanium possesses thermal properties that significantly enhance wearing comfort across different climates and conditions. With a thermal conductivity of approximately 17 W/m·K (compared to stainless steel’s 16-24 W/m·K), titanium transfers heat more slowly, creating a more comfortable wearing experience.

This lower thermal conductivity means titanium watches don’t become uncomfortably cold in winter or excessively hot in summer. Watch enthusiasts often describe titanium as feeling “warmer” than steel in cold conditions – a subtle but meaningful difference during winter months.

Consider a practical example: When moving from a heated building into cold winter air, a stainless steel watch will quickly become cold against the skin, while a titanium watch will maintain a more comfortable temperature for longer. Similarly, titanium heats up more gradually in hot conditions.

This thermal characteristic proves particularly valuable for those who experience rapid temperature changes or engage in outdoor activities across various seasons. For those interested in the science behind these properties, exploring heat resistance in titanium watch cases reveals how this material characteristic translates to enhanced wearing comfort.

Scratch Resistance: Understanding the Nuances

When it comes to scratch resistance, titanium presents a more nuanced picture than many consumers expect. While titanium itself is technically less scratch-resistant than hardened stainless steel alloys, modern manufacturing techniques have largely overcome this limitation.

Titanium’s natural oxide layer does provide some protection against minor abrasions. However, the metal’s inherent hardness (approximately 6 on the Mohs scale, compared to some hardened steels at 7-8) makes it theoretically more susceptible to surface marks.

However, this simplistic comparison doesn’t tell the complete story. Modern titanium watches often employ various treatments to enhance surface hardness:

- Diamond-Like Carbon (DLC) coatings that significantly increase scratch resistance

- Proprietary hardening processes that alter the surface properties of titanium

- Surface treatments that create a more durable exterior while maintaining titanium’s core benefits

Additionally, titanium’s typically matte or brushed finish often makes minor scratches less visible than they would be on highly polished surfaces. Many titanium watches develop a distinctive patina over time that many enthusiasts appreciate as character rather than damage.

For those concerned about durability, exploring titanium watch cases and their scratch resistance provides deeper insights into how different treatments and grades affect long-term appearance.

Different Grades of Titanium in Watchmaking

Not all titanium watches are created equal – various grades of the metal offer different properties and characteristics. Understanding these differences helps explain why titanium watches can vary significantly in performance, appearance, and price.

Two grades dominate watchmaking:

Grade 2 (Commercially Pure) Titanium:

* Composition: 99% pure titanium with minimal alloying elements

* Properties: Excellent corrosion resistance, good formability

* Applications: More affordable titanium watches, cases where maximum strength isn’t required

* Appearance: Slightly darker gray finish

Grade 5 (Ti-6Al-4V) Titanium:

* Composition: 90% titanium, 6% aluminum, 4% vanadium

* Properties: Superior strength (approximately 50% stronger than Grade 2), better machining characteristics

* Applications: High-end watches, complex case designs, components requiring maximum durability

* Appearance: Slightly lighter color, can take a higher polish

Luxury watchmakers often use Grade 5 for its superior properties, while more affordable titanium timepieces typically utilize Grade 2. Some watches even combine different grades – using Grade 5 for structural components and Grade 2 for aesthetic elements.

These material choices significantly influence the evolution of dive watch technology and other specialized timepieces where material properties directly impact performance and longevity.

Titanium vs. Stainless Steel: A Comprehensive Comparison

When considering a fine timepiece, the choice between titanium and stainless steel represents one of the most significant decisions. Each material offers distinct advantages that appeal to different preferences and requirements.

| Property | Titanium | Stainless Steel |

|---|---|---|

| Weight | 40-60% lighter | Substantially heavier, provides “substantial” feel |

| Strength | High strength-to-weight ratio | Good strength, typically requires more material |

| Corrosion Resistance | Exceptional in all environments | Good, but can corrode in extreme conditions |

| Hypoallergenic | Yes (especially pure titanium) | No (contains nickel in most alloys) |

| Scratch Resistance | Moderate (unless treated) | Generally higher in hardened alloys |

| Appearance | Dark gray, matte finish | Bright silver, takes high polish |

| Cost | Typically 20-30% higher | More economical |

| Thermal Properties | Less conductive, more comfortable in temperature extremes | More conductive, faster temperature changes |

Beyond these technical differences, the materials create distinctly different wearing experiences. Stainless steel provides a traditional, substantial feel that many associate with luxury timepieces. Titanium offers a more contemporary, technical character with its lighter weight and distinctive finish.

The choice often comes down to personal priorities – those valuing comfort and lightweight wearability typically prefer titanium, while those who appreciate traditional aesthetics and the reassuring weight of a mechanical watch might prefer steel. For a deeper understanding of material options, exploring the ultimate guide to tough watch cases helps clarify which material best suits specific needs.

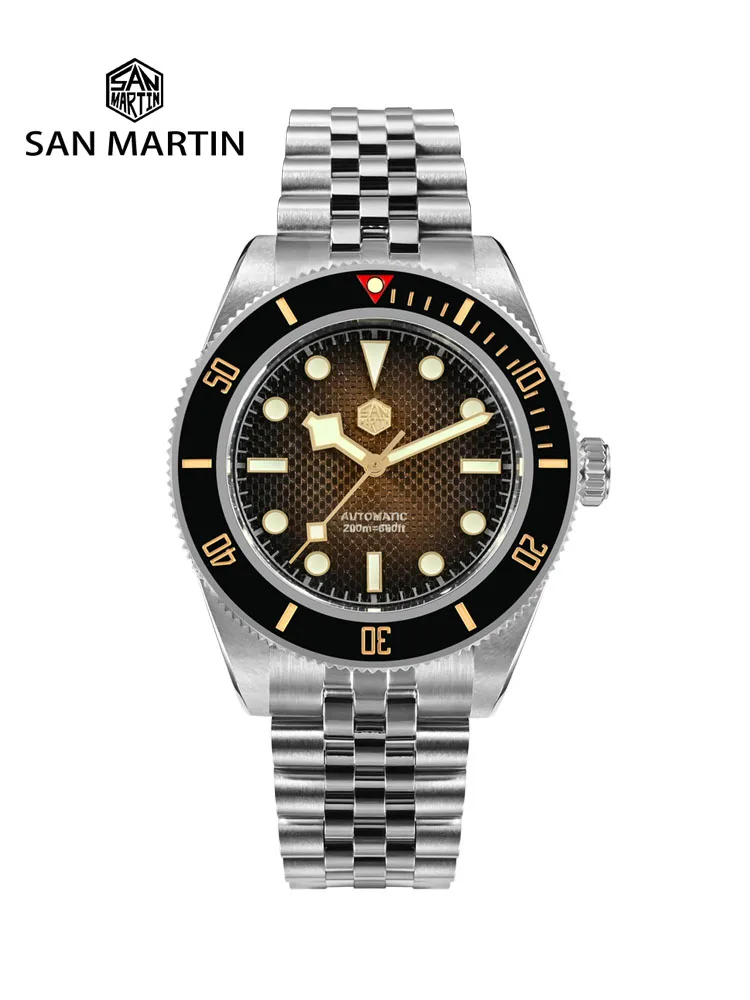

The Aesthetic Appeal of Titanium Watches

Beyond its functional benefits, titanium offers a distinctive aesthetic that appeals to many watch enthusiasts. The metal’s natural appearance – a darker, more subdued gray than stainless steel – creates a sophisticated, contemporary look that complements modern watch designs.

Titanium typically features a matte or brushed finish that diffuses light rather than reflecting it sharply like polished steel. This creates a more subtle, understated appearance that many appreciate for its technical character and resistance to fingerprints and smudges.

The material’s appearance changes subtly over time, developing a unique patina through wear that many enthusiasts consider part of the watch’s character and story. Unlike highly polished metals that show every minor scratch, titanium’s matte finish often masks minor imperfections.

Titanium can be finished in various ways – from industrial sandblasted textures to more refined brushed finishes – allowing for diverse aesthetic expressions. While high polish is more challenging to achieve on titanium, some high-end manufacturers have developed specialized techniques to create more varied finishes.

This distinctive appearance pairs particularly well with contemporary, technical, or sports watch designs, though some manufacturers have successfully incorporated titanium into more classic or dress watch aesthetics as well.

Ideal Applications for Titanium Timepieces

Titanium’s unique properties make it particularly well-suited for specific watch categories and use cases. Understanding these ideal applications helps explain why certain types of watches frequently feature titanium construction.

Dive and Water-Resistant Watches

Titanium excels in marine environments due to its complete immunity to saltwater corrosion. This property, combined with its strength, makes it ideal for professional dive watches that must withstand pressure and exposure to corrosive elements.

Sports and Active Lifestyle Watches

For active individuals, titanium’s lightweight comfort proves invaluable during physical activities. The reduced weight minimizes wrist fatigue during sports, while the material’s durability withstands impacts and harsh conditions.

Travel Watches

Frequent travelers benefit from titanium’s comfort during long journeys. The material’s lightweight nature reduces fatigue during extended wear across time zones, while its hypoallergenic properties prevent skin irritation during long trips.

Everyday Wear Timepieces

As an all-day companion, titanium watches offer superior comfort for professionals and enthusiasts who wear their timepieces continuously. The reduced weight becomes increasingly appreciated over extended wearing periods.

Technical and Tool Watches

Watches designed for specialized purposes often benefit from titanium’s combination of strength and lightness. From pilot’s watches to mountaineering timepieces, these automatic field military watches require materials that perform reliably under stress.

While titanium excels in these categories, it’s worth noting that traditional dress watches still predominantly feature precious metals or steel, as these contexts often value traditional aesthetics and substantial weight.

Innovations in Titanium Watch Manufacturing

The watchmaking industry has developed numerous innovations to enhance titanium’s natural properties and overcome its traditional limitations. These advancements have expanded titanium’s applications in horology while improving performance and aesthetics.

Modern manufacturing techniques have addressed many of titanium’s early challenges. Computer-controlled machining has mastered the material’s difficult machining characteristics, allowing for more complex case designs and bracelets with tight tolerances.

Proprietary surface treatments have revolutionized titanium’s performance:

- Hardening processes that significantly increase scratch resistance without compromising other properties

- PVD and DLC coatings that add color options beyond titanium’s natural gray

- Specialized finishes that create more varied aesthetic possibilities

Some manufacturers have developed proprietary titanium alloys that offer enhanced characteristics for specific applications. These specialized materials push the boundaries of what’s possible with titanium timepieces.

These innovations represent significant milestones in the timeline of diving watch innovations and other horological advancements. As manufacturing technology continues to evolve, we can expect further refinements in titanium watch production, potentially addressing remaining limitations while enhancing the material’s inherent advantages.

Considerations and Potential Disadvantages

While titanium offers numerous benefits for watchmaking, a balanced assessment must acknowledge certain considerations and potential disadvantages. Understanding these factors helps consumers make informed decisions about whether titanium aligns with their priorities.

Cost Implications

Titanium watches typically command a 20-30% price premium over comparable stainless steel models. This higher cost stems from more complex extraction, processing challenges, and specialized manufacturing requirements. For budget-conscious consumers, this premium represents a significant consideration.

Perceived Weight

While many appreciate titanium’s lightness, some traditionalists associate a watch’s quality with substantial weight. The psychological aspect of perceived value can make titanium feel “too light” for those accustomed to heavier timepieces.

Repair and Finishing Challenges

Titanium presents more complex repair scenarios than stainless steel. Specialized tools and techniques are required, potentially increasing service costs. Additionally, refinishing titanium watches requires specific expertise not available at all service centers.

Aesthetic Limitations

Achieving a mirror polish on titanium proves challenging, and color options remain more limited than with other materials. These aesthetic restrictions may not satisfy those seeking highly reflective finishes or diverse color options.

It’s worth noting that many of these considerations reflect subjective preferences rather than objective disadvantages. For a comprehensive understanding of these tradeoffs, exploring the pros and cons of titanium watches helps determine whether the material aligns with individual priorities and preferences.

Is Titanium Right for Your Watch Needs?

Determining whether titanium is the ideal material for your timepiece requires considering several personal factors and preferences. Ask yourself these questions to help make an informed decision:

Do you value comfort and wearability over traditional weight?

If you wear your watch for extended periods or during active pursuits, titanium’s lightweight nature offers significant comfort advantages.

Do you have sensitive skin or metal allergies?

For those with nickel sensitivities or skin irritation from traditional watch materials, titanium’s hypoallergenic properties provide a valuable solution.

Will your watch be exposed to corrosive environments?

If you frequently swim in saltwater, perspire heavily during activities, or expose your watch to harsh conditions, titanium’s corrosion resistance offers peace of mind.

Do you prioritize modern aesthetics over traditional appearances?

Titanium’s distinctive gray finish and typically matte appearance create a contemporary look that might not satisfy those seeking traditional luxury aesthetics.

Is the price premium justified by the benefits for your specific needs?

Consider whether titanium’s advantages align with your priorities enough to justify the typical 20-30% price increase over comparable stainless steel models.

For those seeking to explore various options before deciding, browsing different automatic watches can help clarify which material best aligns with your preferences and requirements.

Military Inspired Automatic Watches, Rugged Automatic Watches, Tactical Automatic Watches

Price range: $852.14 through $994.60 Select options This product has multiple variants. The options may be chosen on the product pageClassic Automatic Dress Watches, Day Date Automatic Watches, Perpetual Calendar Automatic Watches

Price range: $540.60 through $574.60 Select options This product has multiple variants. The options may be chosen on the product pageAutomatic Chronograph Watches, Chronograph Pilot Watches

Price range: $233.36 through $237.58 Select options This product has multiple variants. The options may be chosen on the product pageClassic Automatic Dress Watches, GMT Automatic Watches, GMT Pilot Watches

Price range: $1,240.86 through $1,463.33 Select options This product has multiple variants. The options may be chosen on the product pageAutomatic Chronograph Watches, Classic Style Dive Watches

$3,053.06 Select options This product has multiple variants. The options may be chosen on the product pageAutomatic Skeleton Watches, Open Heart Automatic Watches

$98.36 Select options This product has multiple variants. The options may be chosen on the product page

The Future of Titanium in Horology

As watchmaking continues to evolve, titanium’s role appears poised for further growth and innovation. Several emerging trends suggest exciting developments on the horizon for this remarkable material in horology.

Advanced manufacturing techniques continue to expand titanium’s possibilities. 3D printing and improved machining processes are enabling more complex designs while reducing production costs, potentially making titanium watches more accessible to broader audiences.

New surface treatments and alloys are addressing traditional limitations. Proprietary finishing techniques are creating more diverse aesthetic options, while specialized composites combining titanium with other materials offer enhanced performance characteristics.

Consumer preferences increasingly align with titanium’s strengths. The growing emphasis on comfort, wearability, and practical performance plays to titanium’s natural advantages, driving greater adoption across various watch categories.

Sustainability considerations may further boost titanium’s appeal. The material’s exceptional durability and longevity align with growing consumer interest in sustainable luxury goods designed to last generations rather than follow fashion cycles.

As these trends converge, we can expect titanium to continue gaining prominence in fine watchmaking. The material’s unique combination of properties positions it perfectly for contemporary horology’s focus on titanium rugged watches and durability while maintaining the artistry and craftsmanship that define exceptional timepieces.