Introduction: Why Watch Case Materials Matter

When investing in a quality timepiece, the case material plays a crucial role in determining its durability, longevity, and overall performance. A truly “tough” watch case offers essential protection against impacts, environmental factors, and daily wear while maintaining its aesthetic appeal over time.

The durability of your watch depends significantly on the materials used in its construction. These materials not only affect the watch’s ability to withstand scratches and impacts but also influence its weight, comfort, and even how it ages. For watch enthusiasts and everyday wearers alike, understanding these materials can help you make an informed decision about which timepiece will best serve your needs.

Three key factors determine a watch case’s toughness:

– Material properties (hardness, tensile strength, corrosion resistance)

– Construction techniques (case design, thickness, protective elements)

– Surface treatments (coatings and hardening processes)

Different environments demand different levels of protection. A watch destined for deep-sea diving requires materials with excellent pressure resistance and corrosion protection, while rugged watch cases for outdoor adventures need superior impact resistance and overall durability. Even everyday wear presents challenges from door frames, desk surfaces, and accidental bumps.

In this guide, we’ll explore the full spectrum of materials used in tough watch cases, from traditional metals to cutting-edge composites, helping you understand what makes each option unique.

Traditional Metals in Tough Watch Cases

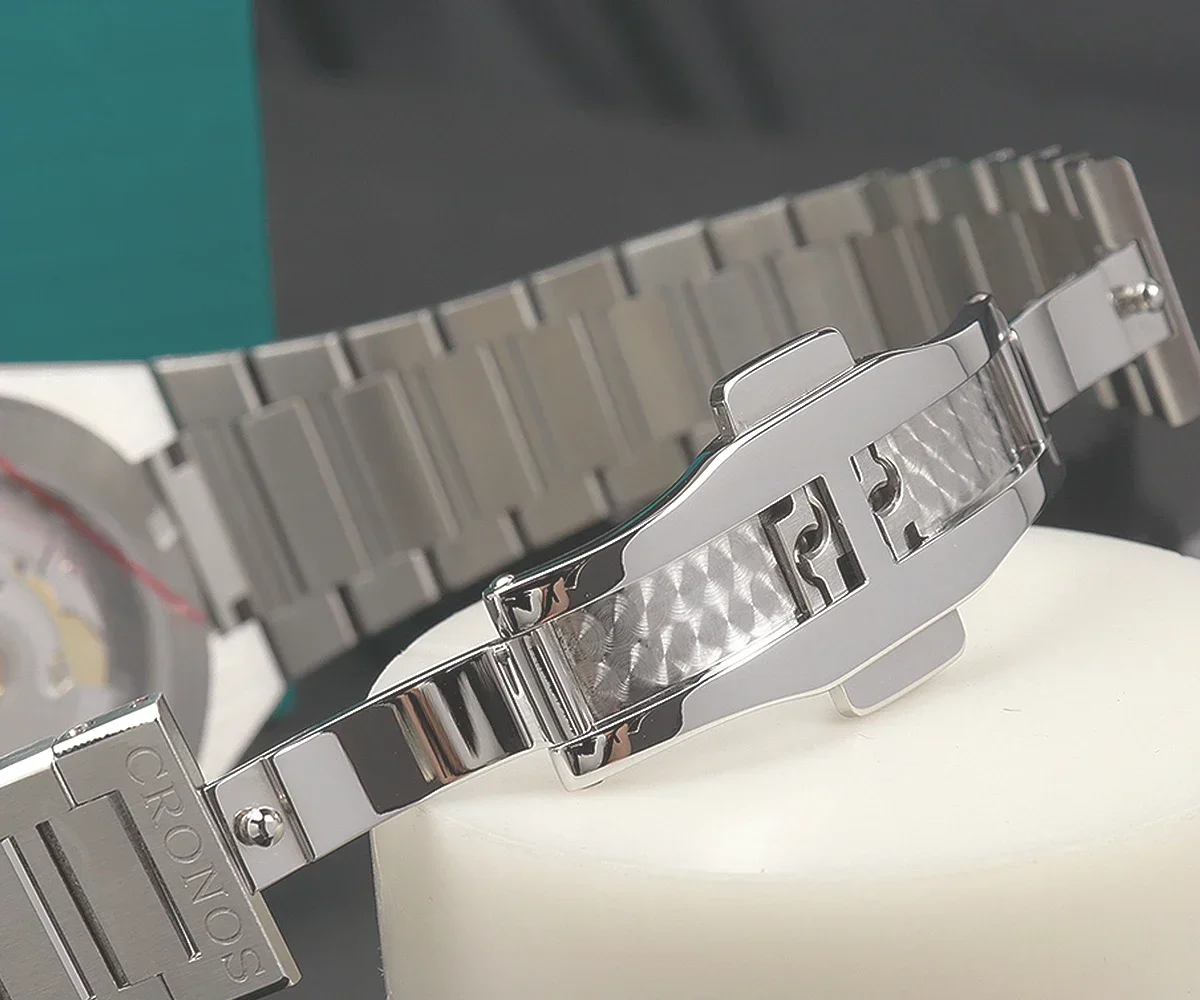

Stainless Steel Variations

Stainless steel remains the most widely used material for quality watch cases, and for good reason. It offers an excellent balance of durability, corrosion resistance, and value. The most common variant, 316L stainless steel (often called “surgical steel”), contains molybdenum, which significantly enhances its resistance to salt water and acids.

This material typically scores around 150-200 HV on the Vickers hardness scale, providing good resistance to everyday scratches and impacts. Additionally, 316L steel is hypoallergenic, making it suitable for most wearers, even those with sensitive skin.

Some luxury manufacturers opt for 904L stainless steel, which offers superior acid resistance and can take a higher polish. However, this improvement comes at a significant cost increase, which explains its limited use to high-end timepieces.

Advantages of stainless steel include:

– Exceptional cost-to-durability ratio

– Excellent corrosion resistance

– Good impact resistance

– Easy to machine and finish

– Compatibility with various surface treatments

Limitations include higher weight compared to some alternatives and susceptibility to scratching, especially with polished finishes. These characteristics make stainless steel particularly well-suited for professional-spec dive watches where durability and water resistance are paramount.

Titanium Grades and Properties

Titanium has revolutionized the watch industry by offering exceptional strength with dramatically reduced weight. Approximately 45% lighter than steel but with comparable strength, titanium provides outstanding comfort for extended wear. Two primary grades appear in watchmaking:

Grade 2 titanium (commercially pure) offers excellent corrosion resistance and is lighter than steel, though somewhat softer. Grade 5 titanium (Ti-6Al-4V alloy) contains 6% aluminum and 4% vanadium, significantly improving strength while maintaining lightness. Grade 5 titanium typically measures 300-400 HV on the Vickers scale before treatment, making it naturally harder than most stainless steels.

Both grades develop a natural oxide layer that provides remarkable resistance to corrosion, even in marine environments. This same process allows minor scratches to become less noticeable over time as the material oxidizes. The metal’s hypoallergenic properties make titanium rugged watches for durability ideal for those with sensitive skin or metal allergies.

Titanium’s advantages include:

– Exceptional strength-to-weight ratio

– Superior corrosion resistance

– Naturally hypoallergenic

– Non-magnetic properties

– Distinctive matte gray appearance

Its main limitations involve higher manufacturing costs (titanium is more difficult to machine than steel) and potential surface scratching, though the oxide layer helps mitigate the visibility of minor scratches over time.

Bronze: Maritime Tradition Meets Durability

Bronze watch cases offer a distinctive aesthetic that connects to maritime history while providing excellent durability. Typically composed of CuSn8 (92% copper and 8% tin) or similar alloys, bronze watches develop a unique patina over time that not only creates a one-of-a-kind appearance but also helps protect the underlying material.

This patination process happens naturally as the copper in the bronze reacts with oxygen, moisture, and other environmental factors. The result is a protective layer that shields the metal from further corrosion while creating rich, warm tones that range from golden brown to deep green, depending on exposure.

The advantages of bronze automatic watches include:

– Distinctive aesthetic character that evolves over time

– Excellent resistance to seawater corrosion

– Historical connection to maritime instruments

– Antimicrobial properties

Limitations include potential skin reactions (the copper can sometimes leave a greenish tint on skin), a slightly lower hardness compared to steel (though still durable), and the fact that the patina development process isn’t for everyone—some prefer the consistent appearance of non-patinating metals.

Advanced Materials for Ultimate Toughness

Ceramic: Virtually Scratchproof

Ceramic watch cases represent a significant advancement in scratch resistance technology. Primarily composed of zirconium oxide (ZrO2), these cases undergo a complex manufacturing process involving fine powder that’s pressed into shape and then sintered (heated) at extremely high temperatures to create an incredibly dense material.

The resulting ceramic boasts impressive hardness ratings of 1200-1600 HV on the Vickers scale (8-9 on the Mohs scale), making it virtually impervious to scratching from everyday objects. To put this in perspective, only diamond and a few synthetic materials are harder than ceramic watch components.

Beyond scratch resistance, ceramic offers several benefits:

– Lightweight properties (approximately 30% lighter than steel)

– Permanent color that never fades or dulls

– Complete corrosion resistance

– Hypoallergenic qualities suitable for sensitive skin

However, ceramic’s extreme hardness comes with a trade-off: brittleness under sharp, concentrated impacts. While highly resistant to scratching, ceramic can crack or shatter if subjected to significant point impacts. Additionally, repairs typically require complete component replacement rather than refinishing.

Understanding the relationship between different durability factors in rugged watches helps explain why many manufacturers use ceramic strategically for bezels while employing other materials for the main case.

Carbon Fiber and Composites

Carbon fiber has established itself as a premium material in the watch industry, offering an extraordinary strength-to-weight ratio. Created through a process where carbon threads are woven into a cloth, layered with resin, and then bonded under heat and pressure, carbon fiber watch cases are approximately 50% lighter than titanium while maintaining impressive structural integrity.

Beyond pure carbon fiber, many manufacturers employ carbon composites—materials that combine carbon fiber with other components like polymers or resins. These composites can be engineered to provide specific performance characteristics while maintaining the distinctive woven aesthetic that carbon fiber is known for.

Key advantages include:

– Unmatched lightweight properties

– Exceptional strength and rigidity

– Complete corrosion resistance

– Distinctive visual texture

– Natural dampening properties that help protect the movement

The main limitations involve a distinctly modern aesthetic that may not suit traditional tastes, complex manufacturing processes that increase cost, and limited repairability if damaged.

Proprietary Brand Compounds

Several watchmakers have developed their own proprietary materials to achieve specific performance characteristics. These innovative compounds typically combine elements of various base materials to create unique properties:

- Carbonox™ (Luminox): A carbon-based compound offering exceptional durability with minimal weight

- Ceratanium® (IWC): Combines titanium’s lightness with ceramic’s scratch resistance

- Breitlight® (Breitling): A polymer-based composite that’s lighter than titanium and highly resistant to scratches, corrosion, and magnetism

These materials often deliver impressive performance metrics, sometimes outperforming traditional materials in specific areas. For example, some proprietary compounds offer the lightweight properties of titanium with significantly improved scratch resistance.

For those seeking the perfect balance of lightweight comfort and exceptional durability, titanium automatic watches provide a proven alternative to these newer proprietary materials.

Surface Treatments That Enhance Toughness

DLC Coatings: Diamond-Like Protection

Diamond-Like Carbon (DLC) coatings represent one of the most significant advancements in watch case protection technology. Applied through either Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD), these microscopically thin carbon coatings dramatically improve the surface hardness of the base material.

With hardness ratings that can reach 3000-9000 HV, DLC coatings provide exceptional scratch protection while maintaining the structural properties of the underlying metal. The coating typically appears black, though variations in the process can produce other dark colors, giving watches a distinctive tactical appearance.

Key benefits include:

– Dramatic improvement in scratch resistance

– Enhanced corrosion protection

– Sleek aesthetic appeal with a modern look

– Relatively thin coating that doesn’t alter case dimensions

However, DLC has limitations. The coating can potentially chip if subjected to extreme impacts, and once damaged, the exposed base material may contrast visibly with the coating. These characteristics make DLC particularly well-suited for tactical automatic watches where both performance and aesthetic considerations are important.

Case Hardening Techniques

Unlike coatings that add layers to the surface, case hardening techniques actually modify the structure of the base material to improve its properties. Notable examples include:

- Tegimenting (Sinn): A proprietary process that increases the base hardness of the steel itself to approximately 1200 HV

- Kolsterising®: A low-temperature carbon diffusion process that hardens the surface without affecting the material’s dimensions

- Cold-working hardening: Mechanical processes that compress the surface molecules to increase hardness

These techniques offer the advantage of improved scratch resistance without adding a separate layer that could potentially delaminate. The hardened material becomes part of the watch case itself rather than a coating on top.

The primary benefits include:

– Increased scratch resistance without changing the appearance of the metal

– No risk of coating delamination or chipping

– Often more subtle appearance than coated options

– Maintained dimensional tolerances

The main limitation is that while these techniques significantly improve scratch resistance, they may not provide the same level of protection against impacts or dents that more elastic materials offer.

Understanding Hardness Scales for Watch Cases

To make informed decisions about watch case materials, it’s helpful to understand how hardness is measured and what the numbers actually mean for real-world performance.

The Vickers hardness scale (HV) is most commonly used in watchmaking. It measures a material’s resistance to penetration by applying a specific amount of force through a diamond indenter. Higher numbers indicate greater hardness:

- Stainless steel: 150-200 HV (untreated)

- Titanium Grade 5: 300-400 HV (untreated)

- Hardened steel: 700-1200 HV (depending on treatment)

- Ceramic: 1200-1600 HV

- Sapphire crystal: 2300 HV

- Diamond: 10,000 HV

The Mohs scale, which ranges from 1 (talc) to 10 (diamond), is sometimes referenced as well, particularly for crystals and ceramic components:

– Steel: 4-4.5

– Titanium: 6

– Ceramic: 8-9

– Sapphire: 9

– Diamond: 10

It’s crucial to understand that hardness isn’t the only factor in determining toughness. While harder materials resist scratches better, they may be more brittle and prone to cracking upon impact. The engineering behind adventure watch cases involves balancing these properties to create timepieces that withstand both scratches and impacts.

Case Construction Elements That Enhance Durability

Material choice works in conjunction with structural design to create truly tough watch cases. Key construction elements include:

Water Resistance Features:

– Screw-down crowns with multiple gaskets

– Threaded case backs with compression seals

– Helium escape valves for saturation diving watches

– Extra-thick crystals to withstand pressure

Shock Resistance Mechanisms:

– Shock-absorbing movement holders

– Strategic case thickness distribution

– Buffer zones between movement and case

– Specialized gasket systems that absorb impact

Crystal Options:

– Sapphire: Exceptional scratch resistance (Mohs 9) but can be more brittle than alternatives

– Mineral glass: Balanced properties with moderate scratch resistance (Mohs 5-7) and good impact resistance

– Acrylic: Superior impact resistance despite vulnerability to scratches (Mohs 3); can be polished to remove scratches

The most durable watches combine tough materials with intelligent construction. For example, some models feature inner protective cases made from soft, shock-absorbing materials surrounded by harder outer cases that resist scratches. Understanding the principles of shock resistance in watches reveals how these elements work together.

Comprehensive Material Comparison Chart

| Material | Hardness (HV) | Weight (vs. Steel) | Scratch Resistance | Corrosion Resistance | Impact Resistance | Relative Cost | Hypoallergenic | Special Characteristics |

|---|---|---|---|---|---|---|---|---|

| 316L Steel | 150-200 | 100% (reference) | Moderate | High | High | $ | Yes | Excellent all-around performance |

| 904L Steel | 150-200 | 100% | Moderate | Very High | High | $$ | Yes | Superior polish potential |

| Titanium Gr.5 | 300-400 | 55% | Moderate-High | Very High | High | $$ | Yes | Extremely lightweight |

| Bronze | 140-160 | 110% | Low-Moderate | High (with patina) | High | $$ | No | Develops unique patina |

| Ceramic | 1200-1600 | 70% | Very High | Excellent | Low | $$$ | Yes | Cannot be scratched by most materials |

| Carbon Fiber | N/A (composite) | 50% | High | Excellent | Very High | $$$ | Yes | Distinctive visual texture |

| DLC-Coated Steel | 1000-3000+ | 100% | Very High | Excellent | High | $$ | Varies | Black appearance |

| Hardened Steel | 700-1200 | 100% | High | High | High | $$ | Yes | No coating to chip or peel |

This chart provides a general comparison between materials, though specific formulations and treatments can alter these properties. For more detailed information about the best materials for outdoor watch cases, consider your specific usage environment and requirements.

Which Material for Which Watch Type?

Different activities and environments call for specific material characteristics in a watch case:

Dive Watches:

Stainless steel remains a favorite for dive watches due to its excellent corrosion resistance, good impact protection, and ability to withstand pressure. Titanium offers a lightweight alternative with superior corrosion resistance, particularly valuable for extended wear in saltwater environments. Bronze provides a heritage aesthetic with excellent seawater protection, though its patina development means the appearance will change over time.

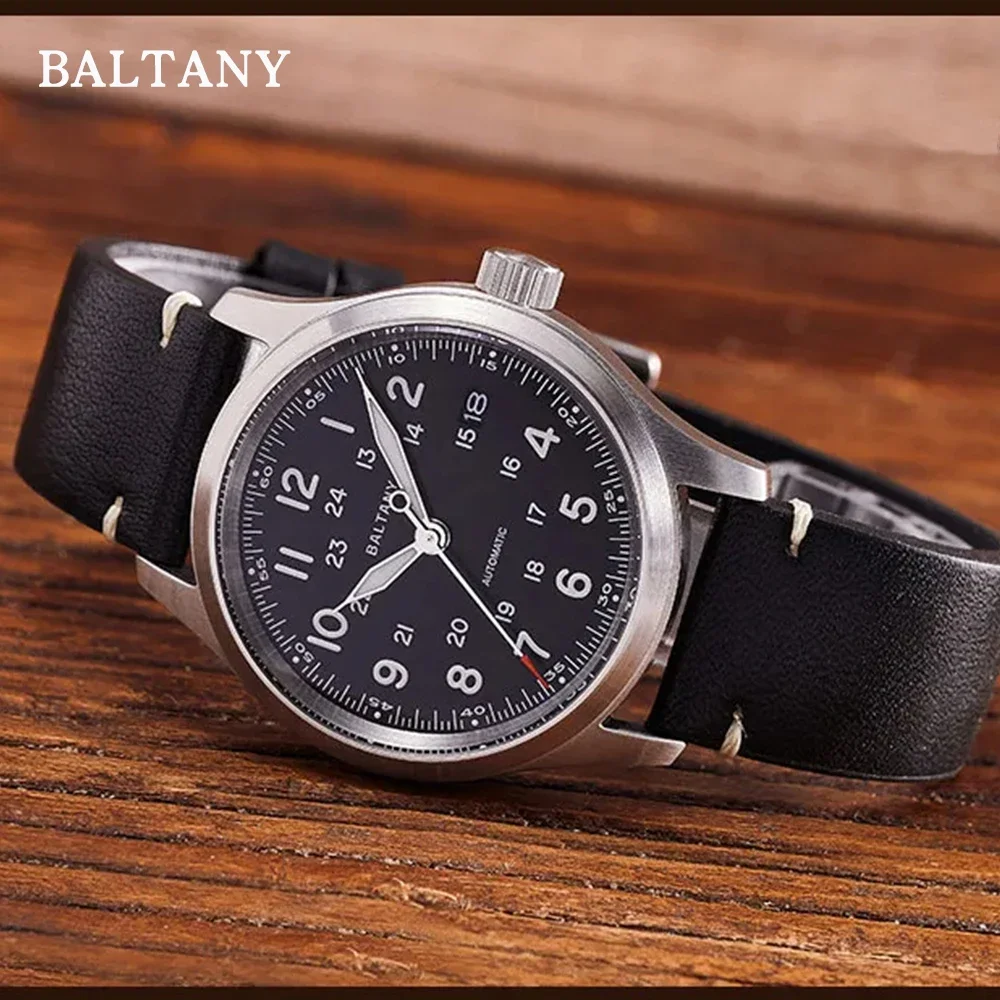

Field/Military Watches:

For tactical and field use, DLC-coated steel provides excellent durability with a non-reflective finish. Titanium balances lightweight comfort with good impact resistance for long deployments. Carbon fiber and composites offer ultra-lightweight options with excellent strength for specialized military applications.

Sports Watches:

Titanium excels for active sports use due to its lightweight comfort and strength. Carbon fiber composites provide even lighter options with good shock absorption. Ceramic components (often bezels) resist scratching during active use, while the main case may use a more impact-resistant material.

Everyday/Dress Watches:

Stainless steel offers the best balance of durability and refined appearance for daily wear. Ceramic provides scratch resistance that maintains a pristine appearance but may be less suitable for rough handling. DLC-coated steel combines durability with a distinctive contemporary look.

For maximum durability across all conditions, rugged automatic watches often combine multiple materials and technologies to create timepieces that withstand extreme conditions while remaining comfortable for everyday wear.

Military Inspired Automatic Watches, Rugged Automatic Watches, Tactical Automatic Watches

Price range: $852.14 through $994.60 Select options This product has multiple variants. The options may be chosen on the product pageBronze Automatic Watches, Military Inspired Automatic Watches, Professional Spec Dive Watches

Price range: $1,442.21 through $1,442.82 Select options This product has multiple variants. The options may be chosen on the product pageProfessional Spec Dive Watches, Titanium Automatic Watches

$574.74 Select options This product has multiple variants. The options may be chosen on the product pageRugged Automatic Watches, Unique Automatic Watches

Price range: $228.96 through $231.10 Select options This product has multiple variants. The options may be chosen on the product pageDay Date Automatic Watches, Professional Spec Dive Watches

Price range: $751.60 through $790.26 Select options This product has multiple variants. The options may be chosen on the product pageClassic Field Watches, Classic Pilot Watches, Rugged Automatic Watches, Titanium Automatic Watches

Price range: $425.24 through $496.28 Select options This product has multiple variants. The options may be chosen on the product page

The Future of Watch Case Materials

The watch industry continues to innovate with new materials that push the boundaries of durability, weight, and aesthetics. Several emerging technologies show particular promise:

Graphene composites offer potentially revolutionary properties with incredible strength, lightness, and flexibility. Though currently limited by production challenges, graphene-enhanced materials could eventually provide unprecedented durability.

Bulk metallic glass (BMG) represents another frontier, combining the hardness of ceramic with the moldability and shock resistance of metal. This amorphous metal structure lacks the crystalline boundaries that create weak points in traditional metals.

Sustainability is increasingly influencing material choices as well. Recycled titanium and steel, bio-based composites, and more environmentally friendly production processes are gaining importance for both manufacturers and consumers.

The balance between tradition and innovation remains crucial in watchmaking. While cutting-edge materials offer impressive performance characteristics, the horological tradition values proven longevity and timeless design. The most successful future materials will likely combine advanced performance with respect for watchmaking heritage.

FAQ: Common Questions About Watch Case Materials

Which material is the absolute hardest for watch cases?

Ceramic currently holds the title for the hardest commercially available watch case material, with Vickers hardness ratings between 1200-1600 HV. However, hardness isn’t the only factor in durability—ceramic can be brittle under impact despite its scratch resistance.

What’s the difference between scratch resistance and impact resistance?

Scratch resistance refers to a material’s ability to withstand surface abrasion without marking, while impact resistance measures how well it absorbs and distributes force without cracking, denting, or breaking. Harder materials typically offer better scratch resistance but may be more brittle upon impact.

Are more expensive materials always more durable?

Not necessarily. While some premium materials like ceramic and carbon fiber offer specific performance advantages, stainless steel remains one of the most durable all-around materials despite its lower cost. The value equation depends on which specific properties matter most for your use case.

How do I care for watches made from different materials?

Stainless steel and titanium can be cleaned with mild soap and water. Bronze should generally be left alone if you want it to develop patina, or can be cleaned with specific solutions to restore its original appearance. Ceramic requires minimal maintenance but should be protected from sharp impacts. Always follow the manufacturer’s care instructions.

Can a scratched watch case be repaired?

It depends on the material. Steel and titanium can often be refinished to remove minor scratches. Bronze naturally develops patina that can hide scratches. Ceramic generally cannot be repaired if scratched (which is rare) or cracked. Coated cases may require complete recoating if the surface treatment is damaged.

How significant is the weight difference between materials?

The weight differences are substantial. Titanium is approximately 45% lighter than stainless steel, while carbon fiber can be up to 50% lighter than titanium. These differences are immediately noticeable when wearing the watch, especially for larger case sizes.

Your Guide to Making an Informed Choice

When selecting a watch case material, consider your lifestyle, aesthetic preferences, and how you’ll primarily use the timepiece. For active outdoor use, the balance of weight and durability offered by titanium or treated steel often provides the best experience. If scratch resistance is your primary concern, ceramic components or surface-hardened steel offer excellent protection.

Remember that no single material is perfect for all situations—each represents a set of trade-offs between hardness, weight, impact resistance, and cost. Many watch enthusiasts eventually acquire timepieces with different case materials to suit various activities and settings.

Your wearing habits and environment play a crucial role in determining the ideal material. Consider whether you’ll be exposing your watch to saltwater, impacts, desk diving scratches, or other specific challenges. The perfect watch case material is ultimately the one that best meets your particular needs while providing the aesthetic appeal you desire.