Introduction: Where Art Meets Engineering in Skeleton Watch Design

Skeleton watches represent the perfect marriage of mechanical artistry and technical innovation in horology. These unique timepieces deliberately expose their beating mechanical hearts through carefully designed transparent elements and cut-away components. Unlike conventional watches that hide their inner workings, skeleton watches celebrate and showcase them—turning the intricate movement into the centerpiece of the design.

The case of a skeleton watch faces a fascinating paradox: it must simultaneously protect the delicate mechanical movement while making it as visible as possible. This fundamental challenge sets skeleton watch case design apart from traditional watchmaking, requiring a completely different engineering approach.

Historically, skeletonization began with pocket watches, where craftsmen would carefully remove excess metal from movements while maintaining structural integrity. As watchmaking evolved, this art transformed from simple cutouts to the sophisticated transparent masterpieces we see today. The evolution of historical dive watch engineering shares similar trajectories of balancing function with form, though skeleton watches push this balance in the direction of visual access.

The perfect skeleton watch case isn’t merely a container—it’s a frame that enhances, protects, and complements the mechanical artwork within. Finding this balance between visibility, protection, and wearability represents one of the most fascinating challenges in modern watchmaking.

Structural Integrity Challenges in Skeleton Case Design

Creating a case for a skeleton watch presents unique engineering challenges. The fundamental dilemma lies in maximizing movement visibility while maintaining structural integrity—two goals that typically work against each other. A conventional watch case derives strength from its solid construction, but skeleton designs must achieve similar strength with significantly less material.

Watch engineers address this challenge through strategic reinforcement. For instance, the lugs (where the strap attaches to the case) often feature additional internal support structures to compensate for the reduced overall case material. Similarly, the case architecture requires careful redistribution of material thickness—areas around openings and transparent sections need additional reinforcement to prevent warping or flexing during daily wear.

Different stress points emerge in skeleton watch cases compared to traditional designs. Areas surrounding sapphire crystal inserts or cutouts require particular attention, as these transitions between materials become potential failure points. Advanced computer modeling has revolutionized this aspect of design, allowing engineers to identify and strengthen these critical areas before physical prototypes are made.

The automatic skeleton watches in today’s market showcase various approaches to this structural challenge. Some manufacturers opt for internal reinforcement ribs that remain largely invisible, while others incorporate the structural elements into the aesthetic design, creating distinctive architectural appearances that turn engineering necessity into visual advantage.

Crystal Engineering: The Window to Mechanical Artistry

The sapphire crystal in a skeleton watch serves dual purposes—it protects the movement while providing the clearest possible view of the mechanical artistry beneath. Unlike standard watch crystals, those designed for skeleton watches must offer exceptional optical clarity with minimal distortion across complex shapes and angles.

Advanced crystal engineering for skeleton watches involves:

- Complex curved geometries that maximize viewing angles while minimizing distortion

- Strategic faceting that reduces reflections and glare that might obscure movement details

- Precision anti-reflective coating application—often on both sides of the crystal

- Perfect dimensional tolerance to ensure water-resistant seals despite complex shapes

The technical challenges of manufacturing these crystals extend beyond shape and clarity. Engineers must account for the different thermal expansion rates between sapphire crystal and metal case components. Without proper allowances, temperature changes could compromise water resistance or even crack the crystal over time.

The ultimate goal of crystal design in skeleton watches is to create what watchmakers call “invisible crystal”—glass so perfectly clear and geometrically optimized that it seems to disappear, creating an unobstructed view of the movement. This quality is particularly evident in many mechanical skeleton watches where the crystal becomes a defining feature of the overall design.

Material Selection for Optimal Balance of Function and Aesthetics

The material chosen for a skeleton watch case dramatically influences its performance, appearance, and feel. Each material presents distinct advantages and challenges for engineers and designers to consider.

Traditional precious metals like gold and platinum offer unmatched luxury and excellent finishing potential but pose challenges for complex skeleton structures due to their weight and relative softness. Stainless steel variants—particularly 316L and 904L—provide better structural stability but require more sophisticated machining when creating intricate skeleton details.

Advanced materials have revolutionized skeleton watch design possibilities:

Titanium alloys provide exceptional strength-to-weight ratios, making them ideal for larger skeleton designs without excessive wrist weight. Titanium automatic watches showcase how this material enables more ambitious skeleton designs while maintaining wearability.

Ceramic composites offer scratch resistance and color possibilities that complement skeleton aesthetics, though they require extremely precise manufacturing due to their brittleness during production.

Carbon composites deliver ultra-lightweight properties with distinctive visual textures that can enhance the technological appearance of modern skeleton designs.

Material selection extends beyond structural considerations—it directly impacts the watch’s tactile experience. For instance, titanium’s low thermal conductivity makes it feel warmer against the skin than steel. Similarly, material choice affects how sound travels through the case, either amplifying or dampening the gentle ticking of the exposed movement.

The expertise developed for outdoor watch cases regarding material durability and performance provides valuable insights for skeleton watch design, even though the application priorities differ substantially.

Framing the Movement: Bezel and Dial Architecture

How a skeleton watch frames its movement is as important as the movement itself. The bezel and dial elements create a visual structure that guides the eye and enhances the mechanical display within.

Effective skeleton watch bezel design requires restraint—it should define the watch’s perimeter without drawing attention away from the movement. Some designers opt for minimal bezels to maximize the viewing area, while others use the bezel as an architectural element that enhances the overall design language.

Chapter rings and flange components serve critical functions in skeleton watches:

- They provide necessary hour markers without obstructing movement visibility

- They create depth through layering, enhancing the three-dimensional experience

- They establish a transition zone between the case exterior and the movement

Color theory plays a substantial role in successful skeleton designs. High-contrast elements improve legibility, while complementary colors enhance the visual separation between functional components. Many designers use subtle metallic finishing differences to create visual hierarchy without relying on bold colors that might distract from the movement itself.

The square and rectangular automatic watches in today’s market demonstrate how case shape influences framing strategy. Non-circular cases create distinct viewing angles and often feature specially designed internal structures to accommodate movements originally designed for round cases.

Ergonomics and Wearability Considerations

A skeleton watch must not only look impressive but also wear comfortably on the wrist. The technical requirements for showcasing a movement create unique ergonomic challenges that designers must address through careful engineering.

Weight distribution represents a primary concern in skeleton watch design. The strategic removal of case material creates irregular weight patterns that can make a watch feel unbalanced on the wrist. Designers counter this by carefully positioning heavier components like the mainspring barrel and balance wheel to create natural counterbalances within the visible architecture.

Case profile design requires special attention in skeleton watches. The benefits of slim watch cases must be balanced against the need to protect exposed movement components. Many successful designs create an illusion of thinness through tapered edges while maintaining necessary clearance for mechanical elements.

Lug design significantly impacts how a skeleton watch sits on different wrist sizes. Some manufacturers create articulating or hinged lugs that adapt to wrist contours, while others design shorter lugs with steeper drop angles to accommodate the typically larger diameter of skeleton watches.

The perception of size differs significantly between skeleton and conventional watches. The visual transparency of skeleton designs often makes them appear larger than their actual dimensions suggest. Designers compensate by creating visual breaks and layers that help the eye process the watch as a cohesive whole rather than focusing on its maximum dimensions.

Integrating Functional Elements: Crowns, Pushers, and Lugs

Functional elements like crowns, pushers, and lugs present unique integration challenges for skeleton watch design. These components must maintain their practicality while harmonizing with the watch’s transparent aesthetic.

Crown design for skeleton watches often takes one of two approaches: either minimal integration that visually recedes into the case or bold architectural statements that complement the exposed movement. Either way, the internal sealing mechanism requires special engineering to maintain water resistance without adding visual bulk that might distract from the skeleton display.

Chronograph pushers in skeleton watches demand particular attention. Their internal mechanisms must be robust enough for repeated use while maintaining visual coherence with the rest of the design. Some manufacturers turn this challenge into an advantage by exposing portions of the pusher mechanism, integrating it into the overall skeleton theme.

Lug design represents another critical junction where engineering meets aesthetics. Lugs must remain structurally sound despite case material reduction, while visually balancing the overall composition. Many successful designs extend the skeleton theme into the lugs themselves, creating dramatic transitions between case and strap.

The longevity of automatic watches depends significantly on the durability of these functional components. In skeleton designs, this durability must be achieved without the protective bulk that conventional watches enjoy—creating a fascinating engineering challenge for watchmakers.

Manufacturing Techniques for Skeleton Watch Cases

Creating skeleton watch cases requires specialized manufacturing techniques that go beyond standard watchmaking processes. The combination of precision, transparency, and structural integrity demands methods that can deliver extremely tight tolerances.

Computer Numerical Control (CNC) machining forms the foundation of modern skeleton case production, but with adaptations specific to horological applications. Multi-axis CNC machines create complex internal geometries that would be impossible with traditional methods. Programming these machines requires specialized expertise to maintain perfect material consistency while removing significant amounts of metal.

Electrical Discharge Machining (EDM) plays a crucial role in creating the intricate internal features of skeleton cases. This process uses electrical discharges to precisely remove material in areas where mechanical cutting tools cannot reach. EDM allows for sharp internal corners and complex shapes that define modern skeleton aesthetics.

Laser cutting technology has revolutionized skeleton case production by enabling precise openwork patterns that would be extremely difficult to achieve with mechanical methods. Modern laser systems can create cuts as narrow as 0.1mm with perfect edge consistency—essential for delicate skeleton designs.

The finishing requirements for skeleton cases exceed even those of conventional luxury watches. Internal surfaces that would normally remain hidden become focal points in skeleton designs, requiring hand-finishing techniques like anglage (edge beveling) and perlage (circular graining) on components that are challenging to access.

These manufacturing advances parallel developments seen in the evolution of dive watch technology, though directed toward aesthetic transparency rather than pressure resistance.

Automatic Skeleton Watches, Open Heart Automatic Watches

$98.36 Select options This product has multiple variants. The options may be chosen on the product pageBronze Automatic Watches, Military Inspired Automatic Watches, Professional Spec Dive Watches

Price range: $1,442.21 through $1,442.82 Select options This product has multiple variants. The options may be chosen on the product pageBlack Skeleton Watches, Mechanical Skeleton Watches

Price range: $37.40 through $111.92 Select options This product has multiple variants. The options may be chosen on the product pageProfessional Spec Dive Watches, Titanium Automatic Watches

$574.74 Select options This product has multiple variants. The options may be chosen on the product pageSquare & Rectangular Automatic Watches

Price range: $127.56 through $134.64 Select options This product has multiple variants. The options may be chosen on the product pageAutomatic Skeleton Watches, Mechanical Skeleton Watches

Price range: $166.16 through $169.76 Select options This product has multiple variants. The options may be chosen on the product page

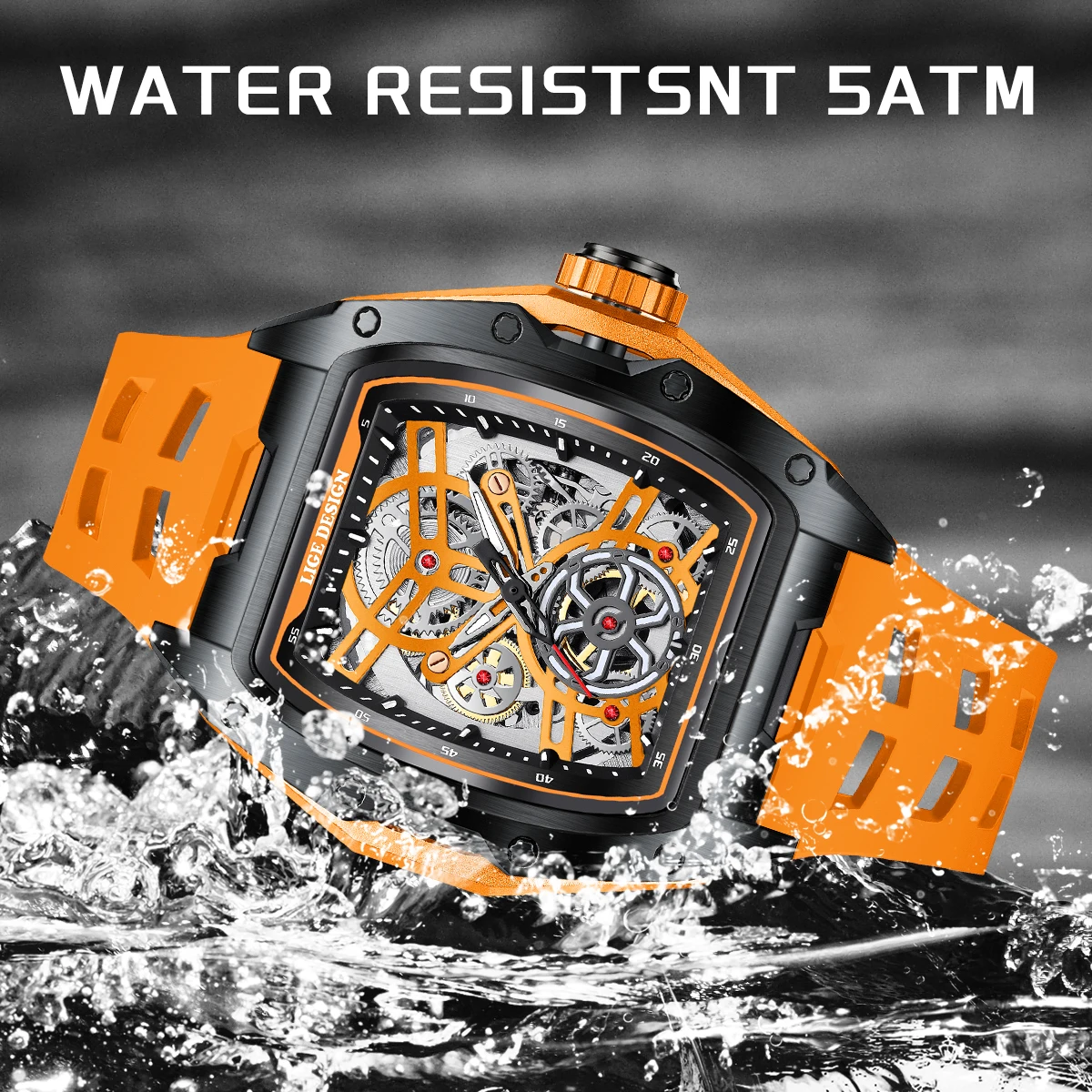

Protecting the Exposed: Dust and Moisture Management

Despite their open design, skeleton watches must still protect their movements from environmental threats—particularly dust and moisture. This protection requires innovative approaches to sealing and gasket design.

Specialized gasket systems for skeleton watches often feature multi-layer designs that provide redundant protection at case openings. These gaskets must be precisely engineered to maintain compression around irregular openings and transparent inserts while remaining largely invisible to the wearer.

Water resistance presents a significant challenge for skeleton designs. While most will never achieve the extreme depth ratings of professional dive watches, they must still withstand everyday moisture exposure. Many manufacturers use composite gasket systems with different materials optimized for specific portions of the case—harder compounds for structural integrity and softer materials for conformability around complex shapes.

Dust protection often proves even more challenging than moisture resistance in skeleton watches. The same openings that make the movement visible also create potential entry points for microscopic particles. Advanced designs incorporate labyrinth seals—overlapping components that create indirect pathways that trap dust particles before they can reach sensitive movement components.

Condensation management requires special attention in skeleton watches due to their large crystal surface areas. Anti-condensation treatments and careful case ventilation design help prevent fog formation that would obscure the very movement the watch is designed to showcase.

Case Studies: Innovative Skeleton Case Design Solutions

The evolution of skeleton watch design has produced fascinating approaches to the fundamental challenges of protection, visibility, and wearability. Examining these design solutions reveals different philosophical approaches to skeleton case engineering.

Architectural-forward designs emphasize the structural elements of the case, creating a framework that becomes part of the aesthetic experience. These designs often feature visible reinforcement elements, dramatic geometric shapes, and material contrasts that highlight the engineering solutions rather than hiding them.

In contrast, minimalist “disappearing” case approaches aim to make the case structure visually recede, creating the illusion that the movement floats on the wrist. These designs use transparent materials, reduced bezels, and hidden attachment points to minimize visual distractions from the movement itself.

Material fusion represents another innovative approach, combining traditional watchmaking materials with modern composites to achieve both visual distinction and technical performance. For example, titanium structural components might support sapphire crystal panels, creating a perfectly transparent viewing experience with adequate protection.

The design differences between skeleton and open-heart aesthetics illustrate how case architecture can completely transform the experience of viewing a mechanical movement. While open-heart designs provide a glimpse of the balance wheel through a single aperture, full skeletonization requires comprehensive case engineering to support and showcase the entire movement.

Supplemental Content: Beyond the Basics of Skeleton Case Design

Are skeleton watch cases more fragile than standard cases?

Not necessarily. While skeleton cases have more openings and transparent elements, they’re engineered with strategic reinforcement in critical areas. The materials and structural design compensate for the reduced material, though they may require more careful handling to avoid damage to exposed components.

Can skeleton watch cases achieve the same water resistance as solid cases?

Typically, skeleton watches offer moderate water resistance (30-50m) rather than the extreme depths possible with purpose-built dive watches. The additional seams and junctions create more potential failure points under pressure, though daily water exposure protection is achievable with proper engineering.

What exactly constitutes a true skeleton case versus a display caseback?

A true skeleton case features multiple viewing points into the movement—typically the front, often the sides, and sometimes the back. Display casebacks only allow viewing from the reverse side, without fundamentally altering the front case design. The difference affects the entire engineering approach to the watch.

Which case materials are most compatible with highly skeletonized movements?

Materials with high strength-to-weight ratios like titanium and carbon composites are particularly well-suited for skeleton designs. Black skeleton watches often utilize these materials to create dramatic contrast with the metallic movement components while maintaining structural integrity with less material.

How do modern skeleton case designs differ from vintage approaches?

Vintage skeleton designs typically modified existing solid cases by adding viewing windows, whereas modern approaches often design the case specifically for movement visibility from the ground up. Contemporary manufacturing techniques allow for more complex geometries and material combinations than were historically possible.

Future Directions in Skeleton Watch Case Design

The evolution of skeleton watch case design continues to accelerate with emerging materials and manufacturing technologies. Advanced ceramics with precisely controlled transparency are beginning to appear in prototype designs, allowing for cases that can transition from opaque to transparent across their surface.

3D printing technologies are revolutionizing prototype development for skeleton cases, allowing designers to test complex geometries and stress distributions before committing to expensive manufacturing processes. As these technologies mature, we may see entirely new structural approaches that aren’t limited by traditional machining constraints.

The integration of electronics with traditional skeleton aesthetics represents another frontier. Some manufacturers are exploring ways to incorporate essential electronic components like automatic lighting or power reserve indicators without compromising the mechanical purity that attracts enthusiasts to skeleton designs.

Sustainability considerations are increasingly influencing material selection and manufacturing processes. Recycled titanium and responsibly sourced materials are becoming more common in premium skeleton watches, addressing growing consumer interest in environmental impact.

The technical distinctions between open heart and skeleton watches continue to evolve as manufacturers explore new ways to reveal mechanical beauty while maintaining practical wearability. This balance of tradition and innovation defines the current direction of skeleton watch design—honoring horological heritage while embracing new possibilities in materials, manufacturing, and aesthetics.

At Sharp Aspect, we continue to follow these developments closely, curating timepieces that represent the pinnacle of skeleton case design while maintaining the structural integrity and reliability our customers expect from premium mechanical watches.