Understanding Slim Watch Movements: The Art of Miniaturization

The world of fine watchmaking celebrates an incredible engineering achievement that often goes unnoticed by the casual observer: the slim watch movement. These mechanical marvels, typically measuring under 3mm in thickness, represent the pinnacle of horological engineering and precision manufacturing.

What makes a watch movement “slim” is not merely its thinness but the extraordinary skill required to compress complex mechanical systems into such confined spaces. Ultra-thin movements (under 2mm) represent the absolute pinnacle of this craft, while slim movements (2-3mm) still demonstrate remarkable engineering prowess compared to standard movements (3mm+).

The fascination with creating thin watches dates back centuries, with royal courts and nobility prizing slender timepieces as symbols of technical mastery and refined taste. The challenge has always remained consistent: reducing thickness without compromising reliability, accuracy, or longevity.

Understanding the relationship between thin case design principles and movement architecture is crucial – the movement largely dictates how slim a watch can ultimately be. While case designers can employ various visual tricks to make watches appear thinner, true slimness begins with the beating mechanical heart inside.

The difference between even 1mm in a movement’s height might seem insignificant, but in watchmaking, it represents a vast dimensional challenge that requires reimagining every component. This comparison between thin and thick watch profiles reveals how movement thickness fundamentally shapes the entire wearing experience.

The Double Challenge: Technical Constraints and Aesthetic Excellence

Creating slim watch movements presents watchmakers with a fascinating paradox: achieving mechanical reliability while eliminating seemingly necessary space. This challenge mirrors the broader tension in horology between technical performance and aesthetic beauty.

Engineers face several critical challenges when designing ultra-thin calibers:

- Structural integrity: Components must remain rigid despite minimal thickness

- Power storage: Maintaining adequate power reserve with a thinner mainspring

- Shock resistance: Protecting delicate parts with minimal space for shock absorption

- Assembly complexity: Working with components that become increasingly delicate as they thin

- Heat and friction management: Controlling these forces in tightly compressed spaces

The solution isn’t simply making everything smaller. Instead, it requires fundamental rethinking of movement architecture, often consolidating components or eliminating traditional elements entirely. For instance, some slim movements eliminate the conventional dial and hands, integrating these into the movement itself.

The pursuit of slimness also directly impacts the watch’s wearability. The benefits of slim watch cases extend beyond mere aesthetics – they include superior comfort, better balance on the wrist, and the ability to slide smoothly under shirt cuffs. Many watch enthusiasts specifically seek thin automatic dress watches for their elegant profile and sophisticated engineering.

This quest for thinness represents the watchmaker’s ultimate challenge: creating mechanical perfection while simultaneously eliminating what seems mechanically necessary.

Key Architectural Innovations in Slim Movement Design

The remarkable thinness of modern slim watch movements comes from revolutionary approaches to traditional movement architecture. These innovations fundamentally reimagine how mechanical watches operate within confined spaces.

Integrated Construction

Traditional movements use a series of plates and bridges to house components. Ultra-thin movements often use the caseback itself as a structural element, eliminating an entire layer. This approach can save 0.5-0.7mm but requires extremely precise manufacturing since the watch case becomes integral to the movement’s functioning.

Micro-Rotor Systems

Standard automatic watches use a full-sized rotor that swings over the movement. Slim calibers employ micro-rotors – smaller, denser winding weights that operate within the same plane as the gear train rather than above it. This innovation alone can reduce thickness by nearly 1mm while maintaining automatic winding functionality.

Peripheral Rotor Design

Taking the concept further, some manufacturers place the winding rotor around the movement’s edge rather than above or within it. This peripheral arrangement maintains winding efficiency while contributing minimally to the movement’s height.

Bridge Elimination

Traditional movements use multiple bridges to support various components. Ultra-thin calibers often integrate these functions into a single plate or eliminate bridges entirely by anchoring components directly to the mainplate.

Innovative Gear Train Layouts

By reimagining the arrangement of wheels and pinions in the gear train, engineers can spread components horizontally rather than stacking them vertically. This approach requires masterful understanding of precision design challenges but results in significantly thinner profiles.

These architectural innovations are particularly evident in minimalist automatic watches where the slim profile directly complements the clean design philosophy. The result is a watch that feels almost ethereal on the wrist while containing hundreds of meticulously crafted parts.

Material Science: The Foundation of Ultra-Thin Engineering

The quest for ever-thinner movements would be impossible without advanced materials science. Traditional watchmaking metals simply cannot maintain structural integrity at the extreme thinness required for ultra-slim calibers.

High-tech alloys like Arcap, a copper-nickel-zinc combination, offer exceptional rigidity despite minimal thickness. These specialized metals enable mainplates and bridges to be machined down to previously impossible dimensions without warping under pressure or over time.

Silicon has revolutionized escapement components in slim movements. Unlike metal, silicon parts:

– Can be manufactured to extraordinarily precise tolerances

– Require no lubrication due to inherently low friction

– Weigh significantly less than metal equivalents

– Resist magnetic interference

– Can be made thinner while maintaining structural integrity

Ceramic ball bearings and jewels have replaced traditional ruby bearings in some ultra-thin designs, offering improved durability despite reduced dimensions. These specialized ceramics maintain precision while occupying minimal vertical space.

Anti-shock systems have been completely redesigned for slim movements. Traditional Incabloc or KIF systems would be too thick, so engineers have developed specialized lateral shock absorption methods that protect delicate balance assemblies without adding height.

These material innovations are particularly evident in automatic dress watches where the sleek profile enhances the formal aesthetic. The marriage of advanced materials with traditional hand-finishing creates movements that are both technically sophisticated and visually stunning.

Component-Level Engineering: Reimagining Traditional Elements

Creating a slim movement requires reimagining every individual component, often reducing parts to mere fractions of their conventional thickness.

Balance Assembly Innovations

The balance wheel and hairspring typically require significant vertical space. In ultra-thin movements, engineers have developed specialized balance wheels that are wider but flatter, with hairsprings that spread horizontally rather than coiling upward. Some designs position the balance wheel on the same plane as the gear train rather than above it, further reducing height.

Mainspring Modifications

Power storage presents a particular challenge in slim movements. Engineers have developed mainsprings that are longer but thinner, often wrapping more tightly around the barrel arbor. Special alloys maintain power delivery despite reduced thickness, though ultra-thin watches typically offer power reserves of 40-50 hours versus the 60+ hours of thicker designs.

Gear Train Refinements

Standard watch wheels might measure 0.3mm thick. In ultra-thin movements, these same wheels might be machined down to 0.12mm – thinner than a human hair – while maintaining perfect teeth profiles and structural integrity. This requires exceptional manufacturing precision, with tolerances measured in microns.

Jewel Bearings

Traditional jewel settings require significant depth. Ultra-thin movements use flush-set jewels that sit directly in the plate without conventional settings, saving precious fractions of millimeters. Some advanced designs use jewels with conical profiles to reduce height further while maintaining durability.

These component-level innovations become particularly visible in skeleton watches that expose movement details, where the extraordinary thinness of individual parts becomes a visual feature rather than merely a technical achievement.

Complications in Confined Spaces: Engineering Marvels

Creating a slim basic movement presents enormous challenges, but incorporating complications—additional functions beyond timekeeping—represents horological wizardry of the highest order.

Date mechanisms traditionally require a separate layer above the base movement. In ultra-thin designs, engineers have developed calendar systems that operate within the same plane as the timekeeping components. Instead of stacking gears vertically, they arrange them peripherally around the dial, maintaining functionality without adding height.

Chronograph mechanisms typically add significant thickness to a watch. Ultra-thin chronographs use column wheels measuring just fractions of a millimeter and clutch systems that engage laterally rather than vertically. The result is a complication that traditionally adds 2-3mm of height compressed into less than 1mm.

The ultimate achievement comes in complicated slim movements that combine multiple functions. Perpetual calendar automatic watches with slim profiles represent extraordinary technical achievements, squeezing hundreds of parts into incredibly confined spaces while maintaining reliability and ease of use.

These complicated slim movements often require years of development, with engineers making thousands of minute adjustments to ensure components operate harmoniously despite having virtually no clearance between parts.

The Manufacturing Challenge: Precision at Microscopic Levels

Creating ultra-thin movements requires manufacturing precision that pushes the boundaries of what’s physically possible.

While standard watch components might be manufactured with tolerances of ±0.01mm (10 microns), ultra-thin movements demand tolerances as tight as ±0.002mm (2 microns). To put this in perspective, a human hair measures approximately 70 microns in diameter, meaning these components must be precise to roughly 1/35th the width of a hair.

Special CNC machines, often developed specifically for watchmaking, produce these components under strictly controlled conditions. Even microscopic temperature variations can affect manufacturing accuracy at this scale.

Assembly presents its own challenges. Watchmakers must manipulate components so thin they can bend if handled improperly, often using specialized tools developed exclusively for ultra-thin movements. The assembly process frequently takes place under microscopes in dust-free environments to prevent any contamination that could interfere with the minuscule clearances between parts.

Quality control becomes extraordinarily demanding for slim movements. Components must be inspected at much higher magnifications, and testing procedures must verify functionality while ensuring the movement remains within its minimal height specifications.

These manufacturing challenges contribute to the exclusivity of classic automatic dress watches with slim profiles, as the production capacity for such technically demanding pieces remains limited compared to standard watch movements.

Iconic Slim Movements That Redefined Watchmaking

Throughout horological history, certain slim movements have pushed boundaries and reset expectations of what’s technically possible.

The race for ultimate thinness has produced remarkable achievements: manual-wind movements measuring just 1.38mm thick and automatic movements barely exceeding 2mm. These accomplishments represent pinnacle achievements in mechanical engineering, often requiring years or decades of research and development.

What makes these iconic slim movements remarkable isn’t just their thinness, but how they maintain reliability despite minimal dimensions. Some approaches prioritize theoretical thinness at all costs, while others balance slimness with practical considerations like serviceability and durability.

Many of these record-setting calibers employ radical designs that look nothing like conventional movements. Some eliminate traditional bridges entirely, while others integrate the case and movement so completely that they become inseparable. These technical innovations have profoundly influenced modern trends in thin watch profiles, inspiring new generations of watchmakers to pursue ever more elegant solutions.

The competition to create the world’s thinnest watch continues driving innovation today, with manufacturers regularly announcing new breakthroughs that seem to defy physical limitations. Each generation builds upon previous achievements, finding clever ways to eliminate fractions of millimeters while maintaining mechanical integrity.

The Practical Realities: Advantages and Trade-offs of Slim Movements

Advantages

- Aesthetic elegance: Creates watches with remarkably sleek profiles

- Enhanced comfort: Sits closer to the wrist and distributes weight more evenly

- Technical prestige: Represents extraordinary engineering achievement

- Versatility: Easily slides under shirt cuffs for formal occasions

- Weight reduction: Generally lighter than standard watches

- Visual harmony: Maintains balanced proportions for smaller wrists

Challenges

- Potentially reduced durability: Less material means less protection against impacts

- Service complexity: Requires specialized expertise for maintenance

- Limited water resistance: Thinner cases typically offer reduced water protection

- Higher production costs: Manufacturing precision and difficulty translate to higher prices

- Power reserve limitations: Smaller mainsprings often store less energy

- Repair costs: Replacement parts may be more expensive and harder to source

Despite their delicate engineering, many slim movements demonstrate remarkable longevity when properly maintained. The key lies in understanding their limitations – these are precision instruments designed for elegant timekeeping rather than extreme sports or harsh environments.

For collectors and enthusiasts, the comfort advantages of thin watch cases often outweigh the potential drawbacks, particularly for those who appreciate fine engineering and elegant aesthetics over rugged functionality.

Classic Automatic Dress Watches, Day Date Automatic Watches, Perpetual Calendar Automatic Watches

Price range: $540.60 through $574.60 Select options This product has multiple variants. The options may be chosen on the product pageClassic Automatic Dress Watches, GMT Automatic Watches, GMT Pilot Watches

Price range: $1,240.86 through $1,463.33 Select options This product has multiple variants. The options may be chosen on the product pageClassic Automatic Dress Watches, Thin Automatic Dress Watches

$437.64 Select options This product has multiple variants. The options may be chosen on the product pageClassic Automatic Dress Watches, GMT Automatic Watches, GMT Dive Watches

Price range: $468.93 through $552.94 Select options This product has multiple variants. The options may be chosen on the product pageClassic Automatic Dress Watches, Minimalist Automatic Watches

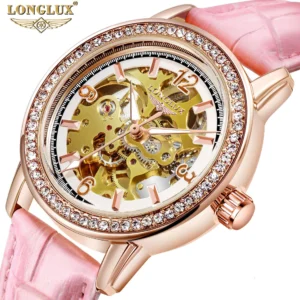

$209.38 Select options This product has multiple variants. The options may be chosen on the product pageAutomatic Skeleton Watches, Classic Automatic Dress Watches

Price range: $139.40 through $155.48 Select options This product has multiple variants. The options may be chosen on the product page

Beyond Thinness: The Future of Slim Movement Innovation

While the race for record-breaking thinness continues, the future of slim movement design extends beyond mere dimensional achievements. Modern innovations focus on improving practical aspects like durability and serviceability while maintaining elegant profiles.

New manufacturing techniques like LIGA (Lithography, Electroplating and Molding) and advanced 3D printing allow for component geometries previously impossible to machine traditionally. These technologies enable parts with variable thickness – robust where strength is needed, ultra-thin where space is critical.

Materials science continues advancing rapidly. Carbon composites, silicon, and ceramics increasingly replace traditional metals in slim movements, offering superior performance characteristics with minimal thickness. Research into new alloys specifically formulated for thin components promises watches that are both slimmer and more durable.

The most exciting developments combine traditional craftsmanship with cutting-edge technology. Hand-finishing and decoration remain essential to fine watchmaking, but these artistic elements now coexist with components manufactured to microscopic tolerances impossible even a decade ago.

This balance between heritage and innovation ensures that slim movements remain relevant in an era of increasingly technical watchmaking. The definitive comparisons of watch case thickness show how these movements enable diverse aesthetic expressions while maintaining the elegant profiles that have captivated watch lovers for centuries.

Are Ultra-Thin Movements Worth the Premium?

Ultra-thin movements typically command price premiums of 30-60% compared to standard movements of similar quality. This raises a natural question: are they worth the investment?

From a collector’s perspective, slim movements represent significant technical achievements worthy of appreciation. The engineering complexity and manufacturing precision required exceed standard watchmaking, justifying part of the premium.

The value proposition becomes particularly compelling when considering dress watches, where the elegance of ultra-thin formal timepieces enhances both aesthetics and comfort. For business attire or formal occasions, the ability of a slim watch to slide effortlessly under a shirt cuff offers genuine functional advantage.

The long-term investment potential of watches with exceptional slim movements also merits consideration. Historically, technically innovative timepieces from respected manufacturers have maintained value well, particularly those featuring movements that represented significant achievements for their era.

Ultimately, the value of a slim movement extends beyond practical considerations. It represents appreciation for mechanical artistry and engineering excellence in an age of disposable technology – a tangible connection to centuries of watchmaking tradition refined to its most elegant expression.

How to Properly Care for Watches with Slim Movements

Watches with ultra-thin movements require thoughtful care to ensure their longevity:

- Service regularly: Have the watch professionally serviced every 3-5 years, preferably by technicians experienced with slim movements

- Avoid impacts: While modern slim watches are more robust than their reputation suggests, minimize exposure to shocks and impacts

- Wind with care: If manually winding, use gentle, deliberate motion rather than forceful winding

- Store properly: Keep in a watch box or winder when not in use to protect from dust and humidity

- Temperature awareness: Avoid extreme temperature changes that can affect lubricants and metal expansion rates

- Water caution: Respect water resistance limitations, which are typically lower than in sports watches

- Magnetic protection: Keep away from strong magnetic sources, as some slim movements have less magnetic shielding

Warning signs that indicate your slim watch needs attention include sudden changes in timekeeping accuracy, unusual noises during winding, or visible condensation inside the case. Addressing these issues promptly can prevent more serious damage.

The evolution of horological elegance shows that slim watches have always commanded respect for their technical sophistication. With proper care, these mechanical marvels can maintain their precision and beauty for generations, making them not just timekeeping instruments but mechanical heirlooms.