Introduction to Adventure Watch Case Construction

Adventure watches represent the pinnacle of horological engineering, designed to withstand conditions that would destroy ordinary timepieces. Unlike standard dress watches, an adventure watch case serves as the primary defense system against harsh environments. These specialized cases shield delicate internal mechanisms from water pressure, shock impacts, extreme temperatures, and corrosive elements.

The durability of adventure watches hinges on three critical factors: the materials selected, construction techniques employed, and protective features integrated into the design. Each element plays a vital role in creating timepieces that function reliably whether you’re diving 300 meters beneath the ocean surface, trekking through freezing mountain passes, or navigating humid rainforests.

The evolution of adventure watch cases has been remarkable. Early pioneers created basic water-resistant designs that have transformed into today’s sophisticated multi-layered protection systems. Modern rugged watch cases for outdoor adventures incorporate decades of field testing and materials science advancements to deliver unprecedented reliability.

Throughout this guide, we’ll explore the engineering principles that make these watches capable of surviving and thriving in the world’s most demanding environments.

The Anatomy of an Adventure Watch Case

Understanding adventure watch durability begins with recognizing the distinct components that form a complete case system. Each element has been refined over decades of watchmaking evolution to serve specific protective functions:

Bezel: The outer ring surrounding the crystal, often rotating on dive watches to track elapsed time. It serves as the first line of impact protection while adding functional capabilities.

Mid-case: The main body housing the movement, providing structural integrity and determining the watch’s overall shape. This component bears the brunt of side impacts and contributes significantly to water resistance.

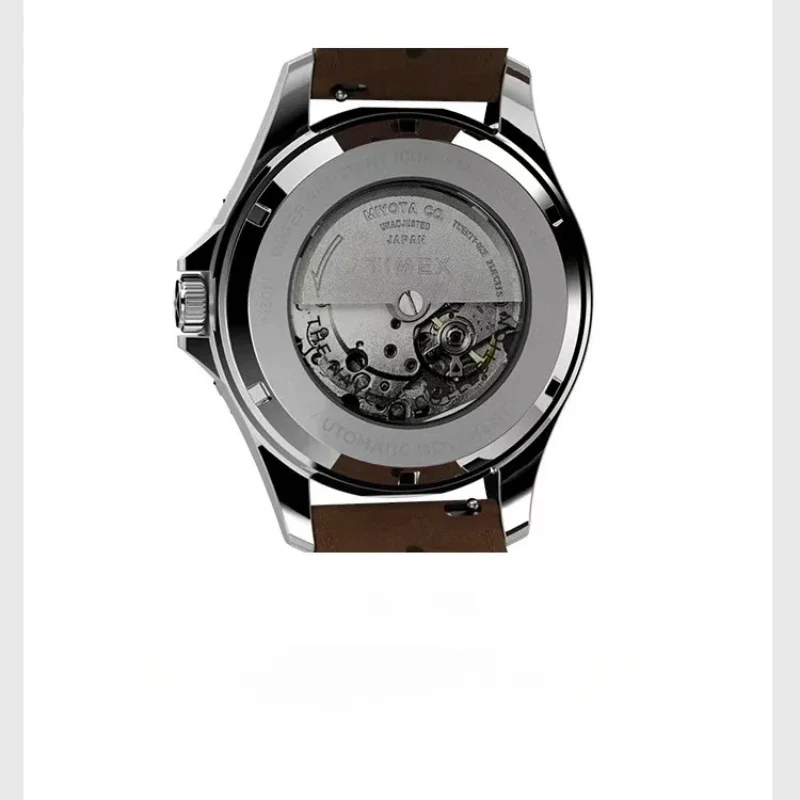

Case back: Seals the rear of the watch, often screwed down or compressed against gaskets to maintain water resistance. May include venting systems for altitude changes in professional models.

Crown: Allows time-setting while presenting a potential vulnerability for water ingress, addressed through screw-down or specialized sealing systems.

Lugs: Connect the case to straps or bracelets, requiring robust engineering to prevent failure during active use.

Pushers: Found on chronographs and multi-function watches, these require specialized sealing systems to maintain case integrity.

The distinction between fashion watches and true adventure timepieces becomes apparent in the engineering approach. While fashion watches often use decorative cases with minimal water resistance, outdoor-ready watch case features incorporate reinforced components, redundant sealing systems, and precision-engineered tolerances measured in hundredths of millimeters.

The integrated versus modular design approach represents a significant differentiation in construction philosophy. Integrated cases machine multiple components from a single block of material for maximum integrity, while modular approaches combine separate pieces to optimize specific properties and serviceability.

Essential Materials for Extreme Durability

The material selection for adventure watch cases fundamentally determines their performance limits, with each option presenting distinct advantages and compromises. Understanding these best materials for outdoor watch cases helps explain why specific watches excel in certain environments.

| Material | Weight | Hardness | Corrosion Resistance | Scratch Resistance | Typical Uses |

|---|---|---|---|---|---|

| 316L Stainless Steel | Moderate | Good (220 HV) | High | Moderate | All-purpose adventure, diving |

| 904L Stainless Steel | Moderate | Good (230 HV) | Exceptional | Moderate-High | Premium dive watches, marine environments |

| Grade 2 Titanium | Light | Moderate (210 HV) | Exceptional | Low | Lightweight trekking, everyday adventure |

| Grade 5 Titanium | Light | High (350 HV) | Exceptional | Moderate | Technical mountaineering, premium sports |

| Carbon Fiber Composite | Very Light | Low-Moderate | High | Moderate | Ultra-lightweight sports, racing chronographs |

| Ceramic | Light | Very High (1200+ HV) | Exceptional | Exceptional | Luxury sports, scratch-resistant applications |

| Bronze | Heavy | Moderate (200 HV) | Develops patina | Moderate | Diving, vintage-inspired adventure |

Material selection directly impacts not only durability but also comfort during extended wear. A titanium case might withstand corrosion better than steel while weighing nearly 50% less—a significant advantage during multi-day expeditions where every ounce matters.

Advanced treatments further enhance these base materials. DLC (Diamond-Like Carbon) coatings add scratch resistance to titanium, while heat treatment processes can increase the surface hardness of steel cases by up to 300%.

Stainless Steel: The Industry Standard

Stainless steel remains the backbone of adventure watch case construction, offering an exceptional balance of durability, corrosion resistance, and manufacturing versatility. This trusted material provides reliable performance across diverse environments without requiring specialized maintenance.

The 316L stainless steel grade dominates the industry due to its excellent combination of:

– Enhanced corrosion resistance from molybdenum content

– Good machinability allowing precise case profiles

– Excellent polish retention for aesthetic longevity

– Superior strength-to-cost ratio compared to exotic materials

For extreme marine applications, some premium manufacturers employ 904L stainless steel, which offers approximately 50% better corrosion resistance than 316L due to higher nickel and chromium content. This upgrade provides meaningful benefits for frequent saltwater exposure but comes with significantly higher material and machining costs.

Many automatic field military watches utilize stainless steel cases with specialized treatments to enhance durability. Cold-forging compresses the steel’s molecular structure for increased hardness, while Tegimented or ice-hardened steel undergoes specialized processes that can triple surface hardness compared to standard steel.

The versatility of stainless steel allows manufacturers to easily incorporate protective features like crown guards, reinforced case backs, and impact-absorbing geometries—making it the preferred choice for watches that must balance durability with serviceability.

Titanium and Advanced Alloys: Lightweight Strength

Titanium has revolutionized adventure watch design by offering exceptional strength with dramatically reduced weight. At approximately 40% lighter than stainless steel with comparable dimensions, titanium provides a comfort advantage during extended wear that’s immediately noticeable.

Beyond weight savings, titanium delivers several critical advantages for adventure applications:

– Superior corrosion resistance, even in saltwater environments

– Excellent temperature stability without becoming uncomfortably cold

– Hypoallergenic properties for sensitive skin

– Natural shock-absorbing flexibility

Grade 2 titanium represents the most common variant in watchmaking, offering good machinability and excellent corrosion resistance. For high-end applications, Grade 5 titanium (with 6% aluminum and 4% vanadium) provides substantially improved hardness and scratch resistance while maintaining the material’s lightweight properties.

Many titanium automatic watches utilize proprietary alloy formulations to address titanium’s primary weakness: susceptibility to surface scratching. Advanced treatments like hardening processes and ceramic-titanium composites significantly improve surface durability while preserving the material’s inherent benefits.

Titanium’s heat resistance properties make it particularly well-suited for extreme environment applications. The material maintains structural integrity across a wider temperature range than steel, preventing distortion that could compromise water resistance seals during dramatic temperature changes encountered in mountaineering or desert environments.

Exotic Materials: Carbon Fiber, Ceramic, and Beyond

Adventure watch engineering has embraced specialized materials that push performance boundaries for specific applications. These exotic options prioritize particular properties like extreme hardness or ultralight weight, often at the expense of traditional durability metrics.

Carbon Fiber Composites:

– Extraordinary strength-to-weight ratio (5x stronger than steel while 40% lighter)

– Natural vibration damping properties that protect movements

– Distinctive woven appearance that signals technical sophistication

– Limited water resistance without additional sealing systems

Ceramic:

– Near-diamond hardness (1200+ Vickers) that virtually eliminates scratching

– Complete corrosion immunity in all environments

– Hypoallergenic properties ideal for sensitive skin

– Brittleness under direct impact requiring careful design considerations

Bronze:

– Develops unique patina reflecting individual wear patterns

– Excellent corrosion resistance under water (historically used in marine equipment)

– Antimicrobial properties that prevent growth on surfaces

– Found in many heritage-inspired bronze automatic watches designed for marine environments

Proprietary materials continue to emerge from advanced research programs. Breitlight® (a polymer composite) offers a case material 3.3 times lighter than titanium with enhanced electromagnetic resistance. Ceratanium combines titanium’s lightweight properties with ceramic’s scratch resistance in a single material, eliminating previous compromise requirements.

These exotic materials typically command premium pricing due to complex manufacturing requirements, specialized tooling needs, and limited production scales. However, they enable performance characteristics impossible to achieve with conventional materials.

Manufacturing Techniques for Maximum Resilience

The transformation from raw material to finished adventure watch case involves specialized manufacturing processes that directly influence structural integrity. These techniques must achieve precision tolerances—often within 0.02mm—to ensure water resistance and component fit.

CNC (Computer Numerical Control) machining dominates modern case production, using multi-axis milling machines to carve cases from solid blocks of material. This approach maintains material integrity without the stress points created by stamping or folding techniques. The process typically follows these stages:

1. Initial block roughing to establish basic dimensions

2. Progressive refinement passes for detail work

3. Interior hollowing with specialized tooling

4. Surface finishing operations for aesthetic and functional purposes

The importance of precision cannot be overstated. Water resistance depends on gasket compression within carefully calculated tolerances—too tight creates distortion, too loose permits water entry. Cases designed for extreme depth ratings (300m+) require even tighter tolerances to maintain integrity under pressure.

Surface hardening treatments applied after machining significantly enhance durability. Black oxide, DLC coating, or nitrocarburizing can increase surface hardness by 200-300%, creating a barrier against scratches without changing the material’s core properties. These treatments prove particularly valuable in understanding durability factors for rugged watches.

Modern manufacturing combines traditional watchmaking knowledge with advanced industrial processes to create cases that can withstand extreme conditions while maintaining precise dimensions necessary for movement operation.

CNC Machining: Precision Engineering

Computer Numerical Control (CNC) machining has transformed adventure watch case production by enabling unprecedented precision and complexity. This process starts with a solid block of material—often weighing 5-10 times more than the finished case—and systematically removes material to create the final form.

The CNC process follows a carefully orchestrated sequence:

1. Initial block facing and centering to establish reference points

2. External profile machining to establish overall shape

3. Interior hollowing to create space for the movement

4. Detail work for thread cutting, gasket channels, and decorative elements

5. Final dimension verification through optical measurement systems

This approach offers several critical advantages for adventure watches:

– Elimination of stress points that exist in formed or welded cases

– Ability to create complex internal structures for improved shock resistance

– Capacity to machine integrated crown guards and protective features

– Consistent production quality across production runs

The precision achievable with modern 5-axis CNC machines is remarkable, routinely holding tolerances of 0.01-0.02mm—approximately one-fifth the thickness of a human hair. This precision directly translates to reliable water resistance and perfect component alignment.

Despite its advantages, CNC machining creates significant material waste—often 60-70% of the original block becomes scrap. This inefficiency contributes to higher production costs, particularly when working with expensive materials like grade 5 titanium or 904L steel.

Multi-Component Case Architecture

Advanced adventure watches often employ multi-component construction that strategically combines different materials and structural elements to maximize protection. This approach allows engineers to optimize each section of the case for specific performance requirements.

The multi-component approach typically includes:

– An outer case providing primary impact protection and aesthetic elements

– An inner movement holder isolating the mechanism from shocks

– Specialized gasket channels ensuring precise seal compression

– Movement suspension systems in high-end models

– Separate bezels that can rotate or absorb impacts independently

This architectural approach enables sophisticated case protection for tactical timepieces that far exceeds what’s possible with simpler construction. By isolating the movement within multiple protective layers, these designs can withstand impacts exceeding 5,000G—more than enough to survive extreme sports or military applications.

Bremont’s Trip-Tick® construction exemplifies this philosophy, using a three-piece case with different materials for each component. The middle section uses hardened steel or titanium for structural strength, while top and bottom components can incorporate different materials optimized for their specific functions.

Multi-component designs allow for easier servicing, as damaged sections can be replaced individually rather than requiring complete case replacement. This modularity extends the functional lifespan of premium adventure watches, offsetting their higher initial cost through improved long-term serviceability.

Water Resistance Engineering

Water resistance represents one of the most critical—and most misunderstood—aspects of adventure watch engineering. The ratings indicated on watch cases (50m, 100m, 200m) reflect static pressure testing conditions rather than actual usage depths, requiring specialized design elements to deliver reliable real-world performance.

Creating effective water resistance requires a comprehensive system approach:

Gasket Networks:

– Multiple independent sealing points create redundancy

– Specialized gasket materials (Viton, NBR, HNBR) selected for specific environments

– Precisely calculated compression ratios (typically 15-25%) to balance sealing force and component stress

– Carefully designed gasket channels preventing displacement during pressure changes

Crown Systems:

– Screw-down mechanisms applying direct compression to gaskets

– Multiple independent sealing points within single crown assemblies

– Thread designs optimized for reliable engagement and gasket compression

– Crown tube integration methods preventing separation under pressure

Case Back Design:

– Screw-in case backs with multi-start threads distributing pressure evenly

– Compression ring designs for specialized applications

– Textured surfaces improving grip during service while enhancing sealing performance

– Vent systems in professional professional-spec dive watches equalizing pressure during helium saturation diving

Verification testing goes far beyond simple pressure checks, with professional certification requiring:

– Static pressure testing at 125% of rated depth

– Dynamic pressure testing with crown manipulation

– Temperature cycle testing simulating rapid environmental changes

– Long-duration immersion testing verifying gasket performance over time

This comprehensive engineering approach explains why properly designed 200m-rated adventure watches can reliably withstand recreational diving, despite the rating suggesting a far lower practical limit.

Crown and Case Back Systems

The crown and case back represent the most vulnerable areas of any watch case, requiring specialized engineering to maintain integrity under pressure and impact. These components incorporate multiple defense systems working in concert to protect the movement.

Advanced crown systems employ multiple protection strategies:

– External crown guards deflecting lateral impacts

– Screw-down mechanisms with 2-3 full turns engaging multiple thread sections

– Triple gasket arrangements creating redundant water barriers

– Shouldered designs preventing over-tightening damage

– Crown tube integration methods eliminating potential failure points

Case back engineering has evolved significantly, with modern designs incorporating:

– Multi-start threading distributing pressure across larger contact areas

– Specialized tools notches preventing slippage during service

– Compression gaskets precisely calculated for optimal sealing force

– Textured patterns enhancing grip while communicating technical capability

Chronograph pushers present special challenges, requiring sealing systems that maintain water resistance while allowing button operation. Solutions include:

– Screw-lock systems requiring unlocking before operation

– Dynamic gasket designs maintaining seal during movement

– Redundant sealing points protecting against operational wear

The materials used for these components often differ from the main case to optimize specific properties. Crown stems may use specialized steel alloys for flexibility and strength, while case back materials might prioritize thermal conductivity to transfer moisture away from gaskets during temperature changes.

These seemingly simple components represent some of the most sophisticated engineering in the entire watch, with development cycles often requiring years of testing to perfect.

Crystal Selection and Integration

The watch crystal serves dual roles as both a viewing window and a critical structural component resisting water pressure. Crystal selection dramatically impacts both durability and visual clarity, with significant performance differences between materials.

Sapphire Crystal:

– Nearly scratch-proof at 9 Mohs hardness (diamond is 10)

– Requires specialized cutting and polishing techniques

– Anti-reflective coatings improve visibility while adding scratch vulnerability

– Excellent pressure resistance when properly dimensioned

– Found in virtually all premium rugged automatic watches

Mineral Crystal:

– Hardened glass offering good scratch resistance at lower cost

– Typically 5-6 Mohs hardness—adequate for casual use

– Can be easily replaced if damaged

– Requires greater thickness for equivalent pressure resistance

– Often used in mid-range adventure watches

Acrylic Crystal:

– Highly impact-resistant but easily scratched

– Can be polished to remove minor scratches

– Excellent shatter resistance in extreme cold

– Limited pressure resistance requiring increased thickness

– Primarily used in vintage-inspired designs or extreme cold-weather applications

The crystal’s contribution to water resistance depends on its mounting method, with two primary approaches:

1. Pressure-fit: The crystal is pressed into a precisely measured channel with gaskets

2. Adhesive mount: The crystal is bonded to the case with specialized sealants

Crystal thickness calculations follow strict engineering formulas considering diameter, pressure rating, and material properties. A typical 100m-rated dive watch might use sapphire crystal 2-3mm thick, while 300m+ professional models often require 4-5mm thickness to maintain integrity under pressure.

Shock and Impact Resistance Systems

Adventure watches face constant impact threats requiring specialized protection systems to prevent movement damage. These engineering solutions must account for impacts coming from any direction while maintaining water resistance and operational reliability.

Modern shock protection incorporates multiple defense layers:

– External case geometry dispersing impact forces

– Internal movement holders creating air gaps between case and mechanism

– Specialized anti-shock systems protecting balance pivots

– Material selection optimizing vibration dampening properties

The ultimate guide to shock resistance in watches demonstrates how these systems work together. When an adventure watch experiences a 1,000G impact (typical in mountain biking or climbing), the force transfers through successive dampening layers before reaching critical movement components.

Technical innovation has produced remarkable advancement in shock resistance:

– Incabloc and Diashock systems protecting balance wheel pivots

– Silicon components eliminating traditional lubrication needs

– Flexible movement ring mounts isolating the mechanism

– Specialized bridge designs distributing forces across wider areas

Testing procedures have become increasingly sophisticated, with standards like ISO 1413 requiring watches to withstand a 1-meter drop onto a hardwood surface. Premium adventure watches often exceed these standards by significant margins, with some G-Shock models rated to survive 10-meter drops onto concrete.

The relationship between shock resistance and case thickness creates challenging design compromises. Engineers must balance adequate protection against wearability concerns, explaining why professional adventure watches often have substantial case dimensions.

Anti-Magnetism and Environmental Protection

Beyond physical impacts and water pressure, adventure watches must withstand invisible environmental threats like magnetic fields, dust, and temperature extremes. Modern engineering addresses these challenges through specialized case construction techniques.

Magnetism represents a significant threat to mechanical movements, with everyday items like smartphone cases generating fields strong enough to affect timekeeping. Protection strategies include:

– Soft iron inner cases creating a Faraday cage effect

– Silicon escape wheels and balance springs resistant to magnetization

– Antimagnetic alloys in movement components

– Multi-layered shields in professional models

Industry standards like ISO 764 require resistance to 4,800 A/m magnetic fields (equivalent to a small household magnet at close range). Advanced adventure watches often exceed this significantly, with some models protecting against fields exceeding 20,000 A/m—strong enough to resist medical MRI equipment.

Temperature protection requires careful material selection and specialized lubricants. Quality adventure watches maintain accuracy from -20°C to +60°C (-4°F to +140°F) through:

– Case materials with matching expansion coefficients

– Temperature-stable gasket compounds

– Special low-viscosity lubricants maintaining performance in extreme cold

– Breathing systems preventing condensation during temperature changes

These protective features demonstrate why purpose-built adventure watches command premium pricing—their ability to function in environments that would quickly disable standard timepieces justifies the additional engineering investment.

Ergonomics and Usability in Harsh Conditions

Even the most durable watch fails its purpose if it cannot be comfortably worn and easily operated in challenging conditions. Adventure watch case design must balance protection with practical usability during activities where dexterity may be compromised.

Critical ergonomic considerations include:

– Crown size and texture optimized for operation with gloves

– Case profile designed to prevent snagging on equipment or clothing

– Lug geometry matching natural wrist contours during activity

– Weight distribution preventing “top-heavy” rotation during movement

These design elements explain the distinct aesthetic of adventure watches—features often misinterpreted as stylistic choices actually serve specific functional purposes. Oversized crowns, integrated crown guards, and angular case profiles all enhance operability in challenging conditions.

The relationship between case diameter, thickness, and wearability creates complex design challenges. Engineers must balance adequate protection against comfort during extended wear, often resulting in distinctive case profiles optimized for specific activities:

– Slimmer profiles for mountaineering watches fitting under layered clothing

– Broader diameters for dive watches maximizing underwater legibility

– Asymmetrical designs for military applications preventing crown damage

These ergonomic considerations demonstrate that adventure watch design extends beyond simple durability metrics to encompass the complete user experience in challenging environments.

Evolution of Adventure Watch Case Design

The development of adventure watch cases represents one of horology’s most significant engineering progressions. From early 20th century experiments to today’s high-tech solutions, each innovation has expanded the boundaries of what watches can withstand.

The first major breakthrough came with screw-down crown systems and threaded case backs, creating watches that could genuinely resist water ingress. These innovations established the foundation for all subsequent adventure watch designs, introducing the concept of multiple defense barriers against environmental threats.

Material innovation transformed case construction capabilities:

– Introduction of 316L stainless steel improving corrosion resistance

– Development of hardened titanium alloys reducing weight while maintaining strength

– Carbon composites enabling previously impossible strength-to-weight ratios

– Ceramic integration providing near-scratch-proof surfaces

Modern rugged watches for extreme conditions incorporate these historical lessons while pushing boundaries through computer-aided design and advanced manufacturing techniques. Today’s adventure watches withstand conditions that would have been unimaginable to early pioneers—depths exceeding 1,000 meters, temperature extremes from arctic expeditions to desert crossings, and impacts that would destroy conventional timepieces.

This evolution continues today with each generation improving on previous limitations. The persistent refinement of adventure watch cases demonstrates watchmaking’s unique combination of traditional craftsmanship with cutting-edge materials science.

Military Inspired Automatic Watches, Rugged Automatic Watches, Tactical Automatic Watches

Price range: $852.14 through $994.60 Select options This product has multiple variants. The options may be chosen on the product pageBronze Automatic Watches, Military Inspired Automatic Watches, Professional Spec Dive Watches

Price range: $1,442.21 through $1,442.82 Select options This product has multiple variants. The options may be chosen on the product pageProfessional Spec Dive Watches, Titanium Automatic Watches

$574.74 Select options This product has multiple variants. The options may be chosen on the product pageClassic Pilot Watches, Military Inspired Automatic Watches

$561.00 Select options This product has multiple variants. The options may be chosen on the product pageRugged Automatic Watches, Unique Automatic Watches

Price range: $228.96 through $231.10 Select options This product has multiple variants. The options may be chosen on the product pageClassic Field Watches, Military Inspired Automatic Watches

Price range: $280.87 through $338.51 Select options This product has multiple variants. The options may be chosen on the product page

How to Evaluate Adventure Watch Case Quality

Armed with understanding of adventure watch engineering, consumers can make informed assessments when evaluating timepiece quality. Several key indicators reveal superior case construction that justifies investment in premium models.

When examining adventure watch cases, look for:

– Crisp, consistent finishing with sharp transitions between surfaces

– Even gasket compression visible when examining crown and case back

– Precise alignment of all external components without gaps

– Smooth crown operation without wobble or inconsistent resistance

– Solid end links with minimal play at bracelet connection points

Material quality often correlates with price point but requires context. A perfectly executed steel case may offer better protection than a poorly designed titanium alternative, despite the material difference. Focus on execution quality rather than materials alone.

The relationship between price and quality follows a logarithmic rather than linear progression. The difference between a $500 and $1,000 adventure watch typically represents significant construction improvements, while the jump from $5,000 to $10,000 often delivers more subtle refinements and exclusive materials rather than proportional durability gains.

For practical durability assessment, examine manufacturer specifications for:

– Specific water resistance testing standards

– Shock resistance certifications beyond minimum ISO requirements

– Temperature range specifications

– Warranty coverage for water resistance failures

These indicators collectively reveal the engineering investment behind the case construction, helping identify watches that deliver genuine capability rather than merely adventure-inspired aesthetics.

Is Case Construction More Important Than Movement Quality?

The relationship between case construction and movement quality creates one of watchmaking’s most interesting debates. Both elements contribute essential value, but their relative importance depends on intended use and personal priorities.

For genuine adventure applications, case integrity logically precedes movement quality—even the finest movement fails if water breaches the case. This hierarchy explains why many professional tool watches combine relatively simple movements with extraordinarily robust cases. The movement must be reliable, but case failure guarantees watch failure regardless of movement quality.

However, this relationship isn’t strictly linear. Case quality directly impacts movement longevity through:

– Protection from environmental contaminants

– Shock isolation preventing balance staff damage

– Temperature stability maintaining lubrication efficacy

– Moisture control preventing corrosion

The optimal approach balances investment across both elements based on intended use. For extreme environments, prioritize exceptional case construction with a reliable but serviceable movement. For daily wear with occasional adventure, a more refined movement in a capable case often provides better overall value.

This balanced perspective explains why many enthusiasts eventually pursue both qualities—appreciating fine movements for their craftsmanship while recognizing that adventure capability begins with the engineering excellence of the external case.

Can Advanced Case Materials Justify Premium Pricing?

The significant price premium commanded by watches using exotic case materials raises legitimate questions about value versus marketing. While certain materials offer genuine performance advantages, others primarily deliver exclusivity without proportional functional benefits.

Materials delivering substantial functional improvements include:

– Grade 5 titanium providing dramatically improved scratch resistance over Grade 2

– Carbon fiber composites reducing weight by 40-50% compared to steel

– Hardened steel alloys offering 3x better scratch resistance than standard steel

Conversely, some premium materials provide marginal practical benefits despite substantial cost increases:

– Precious metals (gold, platinum) offering no durability advantage

– Certain proprietary alloys delivering minimal performance improvements

– Some ceramic formulations that increase brittleness despite scratch resistance

The value equation depends entirely on personal priorities and intended use. For professional applications where specific material properties address real challenges, the premium often represents genuine value. For style-focused consumers, the exclusivity and aesthetic distinction may justify the cost despite limited functional advantages.

The most rational approach evaluates materials based on specific performance needs rather than marketing prestige. Titanium’s lightweight comfort provides genuine benefit during extended wear, while a bronze case’s unique patina development offers aesthetic character unavailable in other materials.

Should You Choose Different Case Materials for Different Adventures?

The diverse environments encountered during different adventure activities suggest potential benefits from matching watch case materials to specific activities. While versatile options exist, certain materials excel in particular scenarios.

For diving and marine environments:

– High-grade stainless steel (316L or 904L) provides excellent corrosion resistance with good impact protection

– Bronze offers similar benefits with distinctive aesthetic evolution

– Titanium eliminates corrosion concerns while reducing weight

For mountaineering and alpine pursuits:

– Titanium’s light weight reduces fatigue during extended expeditions

– Carbon composite’s excellent thermal insulation prevents uncomfortable cold transfer

– Grade 5 titanium resists abrasion from rock contact better than grade 2

For everyday adventure and urban exploration:

– Hardened steel combines scratch resistance with classic aesthetics

– Ceramic bezels protect high-wear areas while maintaining appearance

– DLC-coated cases provide stealth aesthetics with improved surface durability

The decision to specialize versus selecting a versatile option depends on usage patterns and budget. Dedicated enthusiasts often develop collections with watches for specific outdoor activities, while those seeking versatility benefit from titanium’s excellent all-around performance or steel’s balanced properties and lower cost.

This activity-specific approach explains why serious adventurers often own multiple timepieces rather than seeking a single “do-everything” solution—each material offers distinct advantages that may prove decisive in particular environments.

How to Maintain Your Adventure Watch Case for Longevity

Proper maintenance dramatically extends adventure watch lifespan while preserving water resistance and aesthetic appeal. Even the most robust tactical automatic watches benefit from regular care routines adapted to their specific materials and use patterns.

Essential maintenance practices include:

Regular Cleaning:

– Rinse with fresh water after saltwater exposure

– Clean recessed areas (between lugs, around bezel) with soft brushes

– Use appropriate cleaners for specific materials (avoid alcohols on gaskets)

– Dry thoroughly before storage, especially in case crevices

Water Resistance Maintenance:

– Annual professional pressure testing for dive watches

– Replace gaskets during service intervals (typically 3-5 years)

– Ensure crown is fully secured before water exposure

– Avoid extreme temperature changes while submerged

Material-Specific Care:

– Polish stainless steel with appropriate compounds for finish type

– Maintain titanium with specialized protectants avoiding petroleum derivatives

– Allow bronze to develop patina naturally or maintain with mild acidic solutions

– Clean carbon fiber with microfiber only to avoid damaging epoxy matrix

Professional Service:

– Follow manufacturer service intervals (typically 3-7 years)

– Use qualified technicians with correct pressure testing equipment

– Request gasket replacement even during minor service

– Verify water resistance certification after case opening

These practices ensure that the sophisticated engineering in adventure watch cases continues performing as designed, protecting your investment while maintaining reliable performance when it matters most.