Introduction: The Heartbeat of Aviation Timepieces

The chronograph movement in a pilot watch represents far more than an elegant mechanical solution—it’s a vital tool that transforms a simple timekeeper into a precision instrument for aviation. Behind the clean dials and purposeful hands of these timepieces lies intricate engineering specifically designed to meet the demanding needs of flight.

Chronograph movements in pilot watches have evolved alongside aviation itself, with each technical advancement responding directly to the challenges faced by those navigating the skies. These specialized timekeeping engines provide:

- Precise timing capabilities essential for navigation calculations

- Operational monitoring for fuel consumption and flight segments

- Split-second decision support during critical flight phases

- Backup instrumentation when primary systems fail

For those entering the world of chronograph pilot watches, understanding the movement inside is key to appreciating both the functionality and heritage of these remarkable timepieces. In this guide, we’ll explore the various types of chronograph movements, examine iconic calibers that have earned their wings, and provide the knowledge needed to select the right movement for your needs.

As we journey through the technical marvels that power these watches, you’ll discover why Sharp Aspect celebrates these mechanical masterpieces as the perfect embodiment of our philosophy: the harmonious marriage of precision engineering with horological tradition.

The Evolution of Chronograph Movements in Aviation

The story of chronograph movements in aviation begins with necessity rather than luxury. Early pilots faced immense challenges in navigation and flight timing that demanded specialized instruments.

Initially, pilots relied on pocket chronographs, often strapped to their thighs or mounted on instrument panels. These early timing devices allowed for basic calculations of speed, distance, and fuel consumption—calculations that meant the difference between safe arrival and disaster.

As aviation advanced, the transition to wrist-worn chronographs marked a critical evolution. The first dedicated pilot chronographs featured oversized crowns and pushers that could be operated while wearing gloves, with movements designed for legibility and straightforward operation in turbulent conditions.

Military requirements dramatically accelerated chronograph development. Air forces worldwide issued detailed specifications that demanded:

- Greater shock and vibration resistance

- Enhanced magnetic field protection

- Improved legibility in variable lighting conditions

- Specific functions for bombing runs and reconnaissance timing

These military specifications transformed chronograph movements from simple timing devices into robust instruments capable of withstanding the extreme conditions of high-altitude flight and combat operations. Engineers developed new solutions for movement architecture, including reinforced mainplates, specialized lubricants for temperature extremes, and protected balance assemblies.

The evolution continued as pilot watches and aviation history became increasingly intertwined. Movements grew more sophisticated, incorporating slide rule bezels for in-flight calculations, multiple time zones for international flight, and specialized scales for fuel consumption monitoring.

Throughout this development, the connection between aviation needs and military field watch evolution remained strong, with innovations in one area often benefiting the other. The chronograph movements powering these timepieces transformed from simple stopwatches into specialized aviation computers for the wrist.

Understanding Chronograph Movement Fundamentals

Before diving into specific movement types, it’s essential to understand what makes a chronograph movement distinct from a standard watch movement. At its core, a chronograph movement is a timing engine that can measure elapsed time independently from the main timekeeping function.

A chronograph movement contains all the components of a regular watch movement—mainspring, gear train, escapement, and balance—plus an additional module or integrated system that enables the stopwatch functions. This complexity explains why chronograph movements typically have more parts and require more expertise to produce and maintain.

Key Chronograph Functions:

- Start/Stop: Initiates and pauses the chronograph timing system

- Reset: Returns the chronograph hands to zero position

- Split Timing: Some movements allow intermediate time readings while the chronograph continues running

Essential Technical Terms:

- Caliber: The specific model/design of the movement

- Jewel Count: Synthetic rubies that reduce friction (chronographs typically have 25-31 jewels)

- Frequency: Rate of balance wheel oscillation, measured in vibrations per hour (vph)

- Power Reserve: How long the watch runs when fully wound (typically 40-70 hours)

- Column Wheel/Cam System: The mechanism controlling chronograph operations

The architecture of a chronograph movement revolves around several crucial components working in harmony. When a chronograph pusher is activated, it engages a complex sequence: the clutch connects the chronograph to the main timekeeping train, precisely synchronized wheels begin turning, and specialized cams or column wheels control the engagement sequence.

What truly distinguishes fine chronograph movements is how they manage this additional load without affecting timekeeping accuracy. Superior designs isolate the chronograph function to prevent power drain when operating, maintain consistent amplitude, and ensure smooth pusher operation.

Understanding how long automatic watches last is particularly relevant for chronograph movements, as their additional complexity impacts service intervals and long-term reliability. The more complex a chronograph movement becomes, the more crucial proper maintenance becomes for ensuring decades of reliable service.

Manual-Wind Chronograph Movements: Traditional Precision

Manual-wind chronograph movements represent the purest form of chronograph engineering, connecting the wearer directly to the mechanical heart of the timepiece. These movements require daily winding by hand, creating a ritual that many enthusiasts find deeply satisfying.

In the context of pilot watches, manual-wind chronographs carry significant historical authenticity. Many legendary pilot chronographs from the golden age of aviation featured hand-wound movements, as automatic winding was either not yet available or considered unnecessary complexity.

Advantages of Manual-Wind Chronographs:

- Slimmer Profile: Without automatic winding components, these movements can be notably thinner

- Direct Connection: The daily winding ritual creates a tangible relationship with the timepiece

- Mechanical Purity: Fewer parts mean fewer potential points of failure

- Historical Authenticity: True to the design of many classic pilot timepieces

- Visual Appeal: Often feature more elaborate finishing visible through display casebacks

Disadvantages:

- Requires Regular Attention: Must be wound every 1-2 days

- Power Inconsistency: Timekeeping precision can vary as mainspring power depletes

- Less Convenient: Not ideal for those who rotate between multiple watches

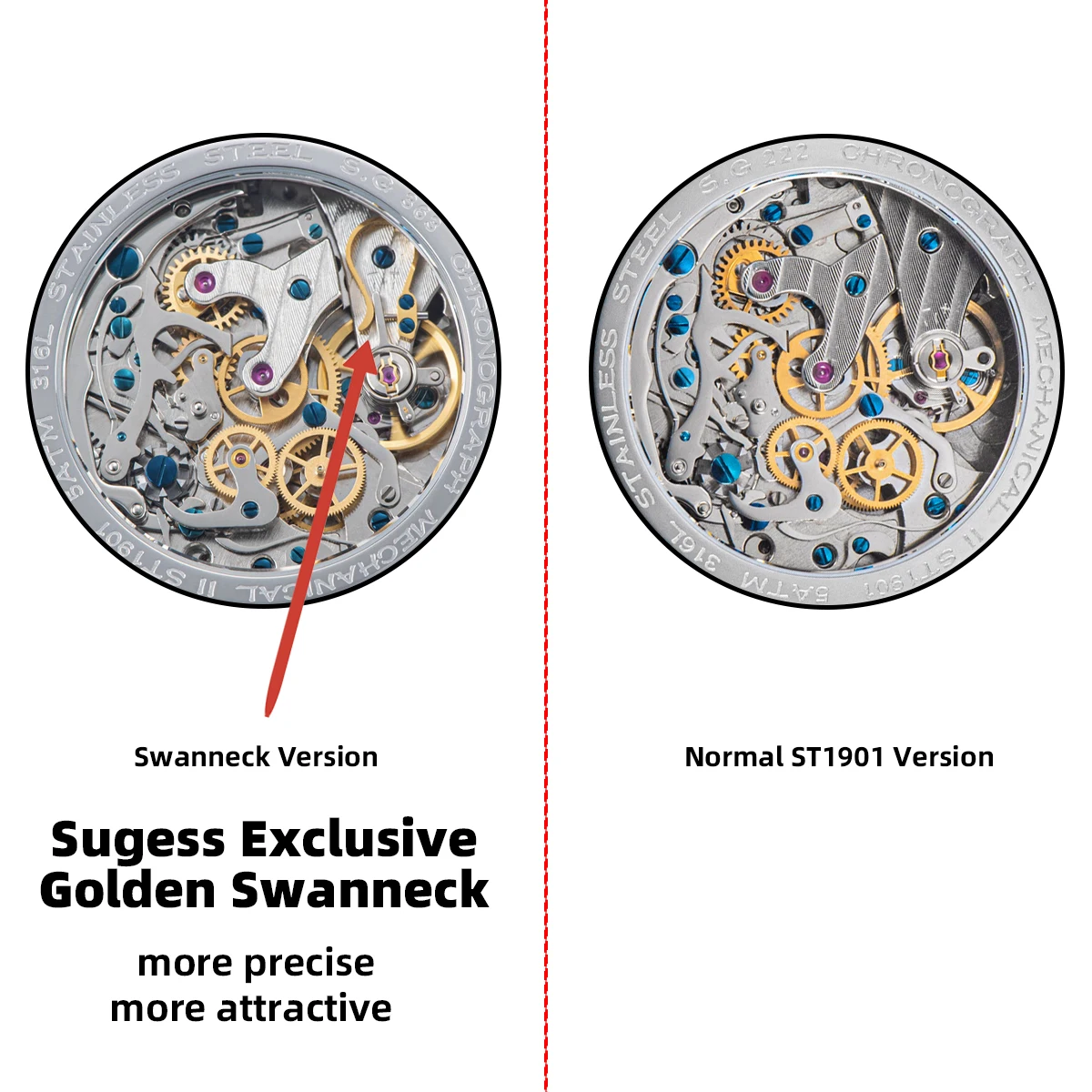

The finest manual-wind chronograph movements feature architecture that has been refined over decades, with traditional column wheel mechanisms that provide a distinctly crisp pusher feel. The absence of automatic winding components allows watchmakers to focus on chronograph functionality and precision.

For pilots and collectors who appreciate mechanical tradition and don’t mind the daily winding requirement, the manual-wind watches offer an experience that connects directly to aviation’s golden era. The tactile feedback when winding the movement creates a personal connection to the timepiece that automatic watches simply cannot replicate.

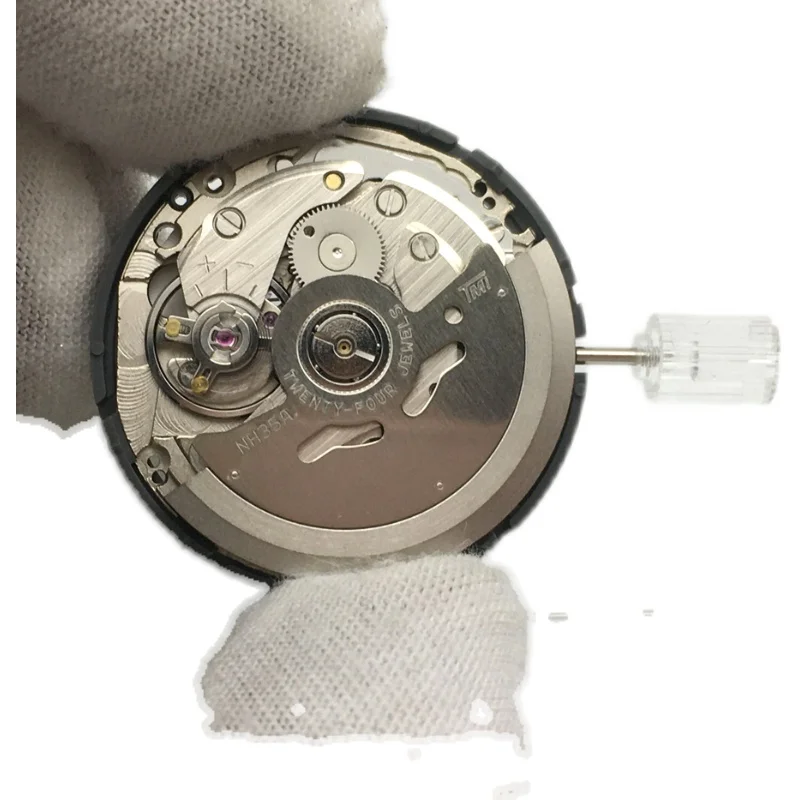

Automatic Chronograph Movements: Modern Convenience

Automatic chronograph movements represent the perfect marriage of convenience and traditional craftsmanship. These self-winding mechanisms harness the natural motion of the wearer’s wrist to maintain consistent power through a weighted rotor that rotates with movement, gradually winding the mainspring.

For pilots, the automatic winding system provides a significant practical advantage—consistent power delivery without daily manual intervention. This ensures that the watch maintains optimal accuracy and that the chronograph function is always ready for use, even after days of inactivity.

Advantages of Automatic Chronograph Movements:

- Consistent Power: Maintains optimal mainspring tension for improved accuracy

- Daily Convenience: Eliminates the need for manual winding when worn regularly

- Ready Availability: The chronograph function is always prepared for immediate use

- Practical For Flight Operations: No need to remember winding during busy flight preparations

- Extended Power Reserve: Many modern automatic chronographs offer 60+ hours of reserve

Disadvantages:

- Increased Thickness: The automatic winding mechanism adds 1-2mm to movement height

- Greater Complexity: More parts mean potentially more expensive service costs

- Weight: The rotor adds noticeable weight to the complete watch

The engineering behind automatic chronograph movements is particularly impressive considering the additional power demands of the chronograph mechanism. Well-designed automatic chronographs maintain a delicate balance between winding efficiency and chronograph operation, ensuring that timing functions don’t deplete the power reserve too rapidly.

Modern automatic chronographs often feature innovations like ceramic bearings for the rotor system, bi-directional winding mechanisms that capture energy from wrist movement in both directions, and optimized mainsprings that deliver more consistent torque throughout the power reserve cycle.

For daily wear and practical pilot use, automatic chronograph watches have become the standard choice, balancing traditional mechanical craftsmanship with modern convenience.

Quartz Chronograph Movements: Precision and Practicality

Quartz chronograph movements represent a fundamental departure from their mechanical counterparts, using electronic oscillations rather than mechanical oscillations to measure time. At their core, these movements rely on the precisely regular vibrations of a quartz crystal powered by a battery.

For professional pilots focused purely on reliable functionality, quartz chronograph movements offer compelling advantages. Their exceptional accuracy—typically within seconds per month rather than seconds per day—means they maintain precise timing even over extended operations.

Advantages of Quartz Chronograph Movements:

- Superior Accuracy: Typically ±15 seconds per month versus ±5-10 seconds per day for mechanical

- Extreme Reliability: Fewer moving parts mean fewer potential failure points

- Shock Resistance: Electronic components generally withstand impacts better than mechanical parts

- Low Maintenance: Requires only battery changes every 2-5 years

- Cost Efficiency: Generally more affordable than mechanical alternatives

- Lightweight: Less mass means more comfort during long flights

Disadvantages:

- Battery Dependence: Requires periodic battery replacement

- Limited Emotional Appeal: Lacks the artisanal value of mechanical movements

- Shorter Lifespan: Electronic components eventually fail and cannot be replaced indefinitely

The technical advances in quartz chronograph movements have been remarkable, with modern versions offering split-second timing, multiple alarms, perpetual calendars, and other advanced functions that would require extremely complex and expensive mechanical solutions.

For pilots operating in environments with high electromagnetic fields or extreme temperature variations, specialized quartz chronographs with enhanced protection and temperature-compensated movements offer reliability that mechanical watches simply cannot match.

While quartz chronographs might not have the emotional appeal of their mechanical counterparts, their practical advantages have earned them a permanent place in professional aviation. The evolution of dive watch technology shows a similar practical divergence, with both mechanical and quartz options finding their respective audiences based on specific needs.

Mecha-Quartz Movements: The Hybrid Approach

Mecha-quartz movements represent an ingenious compromise between electronic precision and mechanical feel. These hybrid systems combine a quartz-regulated timekeeping base with a mechanical chronograph module, offering a unique blend of attributes from both worlds.

The principle is straightforward yet effective: the main timekeeping functions operate via a quartz movement for superior accuracy, while the chronograph functions use mechanical levers, gears, and cams to create the tactile experience of a mechanical chronograph. When activating the pushers, users feel the distinctive click and resistance of mechanical components engaging, rather than the soft electronic button feel of a pure quartz chronograph.

Key Advantages:

- Tactile Mechanical Feel: Provides the satisfying pusher action of mechanical chronographs

- Quartz Accuracy: Maintains precision timekeeping without daily variation

- Instant Reset: The chronograph hands snap back to zero immediately

- Cost Efficiency: Offers mechanical chronograph experience at a fraction of the price

- Low Maintenance: Requires only battery changes rather than full mechanical services

Notable Limitations:

- Compromise Position: Satisfies neither mechanical purists nor those seeking full quartz functionality

- Limited Prestige: Typically not found in luxury watch offerings

- Battery Dependence: Still requires periodic battery replacement

The mechanical chronograph module in quality mecha-quartz movements often provides a smoother sweep for the chronograph second hand than standard quartz chronographs, typically operating at 1/5th-second increments rather than the usual one-second tick. This creates a more visually appealing operation that closer resembles mechanical movements.

As with other watch technologies, the development of mecha-quartz draws from innovations across different specialties. The history of professional diving watches reveals similar hybrid approaches where traditional methods and modern technologies combine to address specific performance needs.

Movement Comparison: Choosing the Right Engine for Your Pilot Watch

When evaluating chronograph movements for pilot watches, understanding the comparative strengths and weaknesses of each type becomes essential. The following analysis breaks down key performance metrics across major movement categories to guide your selection.

| Criteria | Manual Mechanical | Automatic Mechanical | Quartz | Mecha-Quartz |

|---|---|---|---|---|

| Accuracy | +/- 5-15 sec/day | +/- 5-15 sec/day | +/- 15-30 sec/month | +/- 15-30 sec/month |

| Power Source | Hand winding | Self-winding + hand | Battery (2-5 yrs) | Battery (2-5 yrs) |

| Maintenance | Every 5-7 years | Every 5-7 years | Battery only | Battery + occasional service |

| Shock Resistance | Moderate | Moderate | High | Moderate-High |

| G-Force Tolerance | Movement-dependent | Movement-dependent | Very High | High |

| Operation Feel | Excellent | Excellent | Basic | Good to Excellent |

| Price Range | Moderate to Very High | High to Very High | Low to Moderate | Low to Moderate |

| Heritage Factor | Excellent | Very Good | Limited | Limited |

For professional pilots who prioritize absolute reliability and minimal maintenance, quartz movements offer clear practical advantages. Their superior accuracy, shock resistance, and low maintenance requirements make them ideal for operational use.

However, for those who value the connection to aviation heritage and appreciate mechanical craftsmanship, automatic chronographs strike an excellent balance between convenience and tradition. They offer the reliability of self-winding with the satisfaction of mechanical operation.

Manual-wind chronographs appeal most to purists and collectors who appreciate the historical authenticity and direct connection to the mechanism. The daily winding ritual creates a relationship with the timepiece that many enthusiasts find deeply satisfying.

The craftsmanship in chronograph movements varies significantly across these categories, with high-end mechanical movements featuring elaborate finishing and engineering that elevates them from mere timekeepers to mechanical art.

The Valjoux/ETA 7750: Aviation’s Workhorse Movement

No single movement has defined modern pilot chronographs more than the Valjoux 7750 (now produced by ETA). Introduced in the early 1970s and continuously refined since, this robust automatic chronograph caliber has powered countless aviation timepieces across dozens of brands.

The 7750 is an automatic, cam-actuated chronograph movement with a distinctive architecture that has become instantly recognizable to enthusiasts. The movement typically displays a tri-compax layout (three subdials) showing:

- 30-minute counter (typically at 12 o’clock)

- 12-hour counter (typically at 6 o’clock)

- Running seconds (typically at 9 o’clock)

- Date display (typically at 3 o’clock or between 4-5 o’clock)

Technical Specifications:

- Diameter: 30mm (13¼ lignes)

- Height: 7.9mm

- Jewels: 25-31 (depending on version)

- Frequency: 28,800 vph (4Hz)

- Power Reserve: 42-48 hours

- Chronograph System: Cam-actuated

- Winding: Bidirectional automatic

What makes the 7750 particularly well-suited for pilot watches is its proven reliability under adverse conditions. The movement’s robust construction handles vibration well, while its straightforward cam system (rather than more delicate column wheel) provides dependable operation with reasonable service costs.

Pilots and enthusiasts often note the distinctive “wobble” of the 7750’s rotor—a characteristic side effect of its unidirectional winding system. While some consider this a quirk, others view it as part of the movement’s charm and mechanical signature.

The movement’s thickness (nearly 8mm) does necessitate slightly thicker watch cases, but this aligns well with the traditionally robust dimensions of pilot watches. For those seeking a proven chronograph movement with decades of refinement behind it, automatic pilot watches powered by the 7750 and its derivatives remain the industry standard.

The Legendary Lemania 5100: The Military-Grade Movement

While no longer in production, the Lemania 5100 remains one of the most purpose-built pilot chronograph movements ever created. Designed specifically for military and aviation use, this movement prioritized function, legibility, and durability above all else, often at the expense of aesthetic refinement.

What distinguished the 5100 from other chronograph movements was its central chronograph minute hand—a feature that dramatically improved legibility by placing both chronograph seconds and minutes in the center of the dial. This allowed pilots to read elapsed time without shifting focus to a small subdial, a crucial advantage during high-stress flight operations.

Technical Highlights:

- Central chronograph seconds and minutes hands

- Day/date display

- 24-hour indicator

- 30-minute counter

- 12-hour counter

- Running seconds

The 5100’s engineering reflected its military heritage with several unconventional design choices. Rather than prioritizing traditional fine watchmaking aesthetics, it incorporated synthetic components (including Delrin plastic parts) specifically chosen for their shock resistance and low friction. These materials allowed the 5100 to withstand extreme g-forces and continue functioning where more traditional movements might fail.

Military specifications drove the 5100’s development, with requirements including:

– Ability to withstand extreme shock without losing timing or chronograph function

– Operation in varying temperature and pressure conditions

– Continued functionality during high-g maneuvers

– Immediate chronograph start with no “stutter”

This functional focus made the 5100 a favorite among military pilots, and watches containing this movement were issued to air forces worldwide. Today, military-inspired automatic watches often draw design inspiration from the 5100-equipped timepieces, even if they utilize different movements.

For collectors and pilots who value purpose-built functionality over decorative finishing, watches containing the discontinued Lemania 5100 remain highly sought after, representing the pinnacle of dedicated military chronograph design.

High-Frequency Excellence: The Zenith El Primero

The Zenith El Primero stands apart in the world of chronograph movements due to its exceptional high-frequency operation. While most chronograph movements oscillate at 28,800 vibrations per hour (4Hz), the El Primero operates at an impressive 36,000 vibrations per hour (5Hz), allowing it to measure time with greater precision.

This higher frequency provides a tangible advantage for chronograph operation—the ability to measure time increments down to 1/10th of a second rather than the 1/8th second of standard 4Hz movements. For pilots requiring precise timing, this increased resolution can make a meaningful difference in critical calculations.

Technical Excellence:

- Frequency: 36,000 vph (5Hz)

- Power Reserve: Approximately 50 hours

- Architecture: Integrated chronograph design with column wheel

- Chronograph Control: Column wheel with horizontal clutch

- Diameter: 30mm

- Jewel Count: 31 jewels

The El Primero’s integrated design—where the chronograph mechanism is built as an integral part of the movement rather than as a module added to a base caliber—results in a thinner profile and more harmonious operation. The column wheel system provides exceptionally smooth pusher action when starting, stopping, and resetting the chronograph.

This higher operating speed does present engineering challenges, including increased wear and more frequent service intervals. To address these concerns, the El Primero incorporates specialized lubricants and carefully selected alloys that can withstand the increased friction and stress of high-frequency operation.

For pilots who demand the ultimate in mechanical precision and appreciate horological innovation, the El Primero represents a significant step beyond standard chronograph movements. Its development parallels other precision innovations in specialized timepieces, as seen in the timeline of diving watch innovations, where technical advances addressed specific professional requirements.

In-House Aviation Chronographs: Breitling and IWC

As the watch industry has evolved, leading aviation watch manufacturers have increasingly developed their own proprietary chronograph movements, moving beyond the industry-standard supplied calibers. Two brands in particular—Breitling and IWC—have made significant investments in creating in-house movements specifically optimized for pilot use.

Breitling B01 Caliber Family

Breitling’s flagship B01 chronograph movement represents the brand’s commitment to vertical integration and technical excellence. As a true manufacture caliber, it incorporates several technical advantages:

- Column-wheel chronograph control for precise pusher action

- Vertical clutch engagement preventing hand jump when starting the chronograph

- 70+ hour power reserve for extended operation

- COSC chronometer certification guaranteeing precision

- Modular design allowing for various complications

- 1/4th second precision with 28,800 vph frequency

The B01’s architecture was designed specifically for robust reliability, with particular attention paid to chronograph stability during operation. The movement allows for smooth chronograph operation without affecting timekeeping accuracy.

IWC’s 69000 and 89000 Caliber Series

IWC has developed two significant in-house chronograph movement families tailored to their pilot watch collections:

- 69000 Series: A column-wheel chronograph with 46-hour power reserve and classic subdial layout

- 89000 Series: Advanced chronographs featuring flyback function and innovative hour/minute counter displays

The 89000 series in particular shows thoughtful design for pilot use, with its combined hour and minute counter on a single subdial for improved legibility. This allows pilots to read elapsed time more intuitively than with traditional separate hour and minute counters.

Both Breitling and IWC have emphasized shock resistance and antimagnetic properties in their movements, recognizing the demanding environments pilots face. These movements represent significant investments by the brands, with development costs often exceeding millions of dollars.

For collectors and aviation enthusiasts, these in-house movements provide technical advantages while strengthening the connection to brands with authentic aviation heritage. Their development mirrors similar advancements seen in other professional timepieces, as documented in the milestones of underwater watch engineering, where specialized needs drove innovation.

Essential Chronograph Complications for Pilots

Beyond the basic chronograph functionality, several specialized complications provide enhanced utility specifically for aviation applications. These features transform a standard chronograph into a sophisticated flight instrument.

Flyback Function

The flyback complication allows pilots to reset and instantly restart the chronograph with a single pusher press, rather than the traditional stop-reset-start sequence requiring three separate actions. This function was developed specifically for aviation, where pilots need to time consecutive events with minimal distraction.

During navigation sequences or approach procedures, the flyback function enables quick timing transitions without looking away from instruments. The mechanical engineering behind this function is particularly impressive, requiring precisely coordinated components that can reset and re-engage instantly without damaging the movement.

Split-Seconds (Rattrapante)

The rattrapante or split-seconds function incorporates two superimposed chronograph seconds hands, allowing the measurement of intermediate times while the main chronograph continues running. By pressing a dedicated pusher, one hand stops to read an intermediate time while the other continues running, then catches up when the pusher is pressed again.

This complex mechanism enables timing of multiple events with a single chronograph—useful for calculating leg times during navigation or comparing elapsed times between checkpoints.

Central Minute Counter

Pioneered in movements like the Lemania 5100, the central minute counter places the chronograph minute hand in the center of the dial alongside the seconds hand, rather than on a smaller subdial. This dramatically improves readability, allowing pilots to read elapsed minutes at a glance without focusing on smaller subdials.

GMT/Second Time Zone Integration

Many pilot chronograph movements incorporate GMT or second time zone capabilities, allowing simultaneous tracking of local time and UTC (Coordinated Universal Time) or home base time. This integration is particularly valuable for pilots on international routes, who must coordinate between multiple time zones.

GMT pilot watches with chronograph functionality represent the ultimate multi-tasking tool, combining navigation timing with timezone management in a single instrument.

Performance Factors: What Makes a Superior Pilot Chronograph Movement

The demands of aviation require chronograph movements that excel across multiple performance dimensions. When evaluating movements for pilot use, several critical factors determine their suitability for the cockpit environment.

Accuracy Standards

Chronometer certification represents the gold standard for mechanical movement accuracy. COSC (Contrôle Officiel Suisse des Chronomètres) certification requires movements to perform within strict parameters:

- Mean daily rate: +6/-4 seconds per day

- Mean variation: Maximum 2 seconds per day

- Maximum positional variation: 5 seconds per day

- Temperature variation: Maximum +/- 0.6 seconds per day per degree Celsius

- Isochronism: Maximum 2 seconds difference between day 1 and days 4 & 5

For pilot use, this consistent accuracy ensures reliable timing for navigation and operational calculations.

Durability Engineering

Superior pilot chronograph movements incorporate specialized engineering to withstand the aviation environment:

- Shock absorption systems protecting the balance and escapement

- Reinforced movement holders minimizing transmission of case impacts

- Secured chronograph mechanisms preventing disruption during turbulence

- Robust chronograph engagement systems ensuring reliable operation

Anti-Magnetic Protection

Modern cockpits contain numerous electronic systems generating magnetic fields that can disrupt watch movements. Advanced pilot chronograph movements incorporate:

- Silicon balance springs unaffected by magnetism

- Soft iron inner cases creating magnetic shields

- Non-ferrous movement components reducing magnetic susceptibility

Leading movements now offer protection up to 15,000 gauss, far exceeding the magnetic fields typically encountered in aviation.

Power Reserve Considerations

Extended power reserve provides practical benefits for pilots who may not wear their watch daily. Modern pilot chronograph movements often deliver:

- Standard movements: 42-48 hours reserve

- Advanced calibers: 60-70 hours reserve

- Extended power reserve models: 80+ hours

This extended operation ensures the watch remains running and accurate between wearing sessions, eliminating the need for frequent resetting.

The performance standards for aviation chronographs parallel those developed for other extreme environments, as seen in the influence of marine exploration on dive watches, where reliability under adverse conditions is equally critical.

Military Inspired Automatic Watches, Rugged Automatic Watches, Tactical Automatic Watches

Price range: $852.14 through $994.60 Select options This product has multiple variants. The options may be chosen on the product pageAutomatic Chronograph Watches, Chronograph Pilot Watches

Price range: $233.36 through $237.58 Select options This product has multiple variants. The options may be chosen on the product pageClassic Automatic Dress Watches, GMT Automatic Watches, GMT Pilot Watches

Price range: $1,240.86 through $1,463.33 Select options This product has multiple variants. The options may be chosen on the product pageAutomatic Chronograph Watches, Classic Style Dive Watches

$3,053.06 Select options This product has multiple variants. The options may be chosen on the product pageBronze Automatic Watches, Military Inspired Automatic Watches, Professional Spec Dive Watches

Price range: $1,442.21 through $1,442.82 Select options This product has multiple variants. The options may be chosen on the product pageClassic Manual Wind Watches, Manual Wind Dress Watches

Price range: $425.50 through $462.50 Select options This product has multiple variants. The options may be chosen on the product page

In-House vs. Supplied Movements: Quality and Value Considerations

The distinction between in-house and supplied movements represents one of the most discussed topics in watch collecting, with significant implications for both performance and value.

Defining Movement Sources

In-house movements are designed, manufactured, and assembled by the same company that produces the complete watch. They represent significant investment in research, development, and manufacturing capabilities.

Supplied (ébauche) movements come from specialized movement manufacturers (like ETA, Sellita, or Soprod) and are used by watch brands that don’t produce their own movements. These movements are often customized to various degrees by the brands that use them.

The In-House Advantage

Watches with in-house chronograph movements offer several potential benefits:

- Exclusivity: Unique movement designs not available from other brands

- Tailored Engineering: Movements designed specifically for the watches they power

- Brand DNA: Technical expressions of a brand’s specific approach to watchmaking

- Innovation Potential: Freedom to develop novel solutions and complications

- Vertical Integration: Complete control over quality and production

The Supplied Movement Case

Quality supplied movements bring their own significant advantages:

- Proven Reliability: Movements with decades of refinement and millions of units produced

- Established Service Network: Wider availability of qualified technicians worldwide

- Cost Efficiency: Economies of scale reducing production costs

- Accessibility: More affordable entry points to quality chronograph watches

- Standardized Parts: Easier and potentially less expensive service requirements

Value Considerations

The premium commanded by in-house movements varies dramatically depending on the brand and specific caliber, but typically ranges from 30-300% above similar watches with supplied movements. This premium reflects both actual production costs and perceived prestige value.

For pilots who prioritize practical reliability above brand exclusivity, established supplied movements often represent the more pragmatic choice. Their long production history means most potential issues have been identified and resolved, and service solutions are widely available.

The value equation in chronograph movements parallels similar considerations in other specialized timepieces, as explored in the evolution of dive watches’ technical journey, where both in-house and supplied solutions have found success based on different priorities.

Selecting the Ideal Chronograph Movement: A Pilot’s Perspective

Choosing the right chronograph movement for your pilot watch ultimately depends on your specific needs, preferences, and usage scenarios. By focusing on your personal priorities, you can identify the movement characteristics that will provide the most satisfaction.

Professional Pilot Considerations

For active professional pilots, the following factors typically take precedence:

- Reliability under aviation conditions

- Legibility of chronograph displays

- Shock and vibration resistance

- Anti-magnetic protection

- Ease of operation while wearing gloves

- Serviceability and global support network

Many professional pilots find that robust automatic chronographs from established manufacturers provide the ideal balance of performance and practicality. Movements like the ETA 7750 or Breitling B01 offer proven reliability with excellent support networks worldwide.

Enthusiast and Collector Priorities

For aviation enthusiasts and collectors, different factors may drive the selection:

- Movement heritage and aviation connection

- Mechanical sophistication and complications

- Visual appeal and finishing quality

- Brand prestige and historical significance

- Exclusivity and limited production

- Investment potential and resale value

Collectors often gravitate toward in-house movements or historically significant calibers that represent important chapters in aviation watchmaking history.

Selection Checklist

When evaluating chronograph movements, consider these questions:

- What specific timing functions do you need for your flying activities?

- How important is absolute accuracy versus mechanical character?

- Will you wear the watch daily or rotate between multiple timepieces?

- Do you need a movement with global service availability?

- What is your budget for both purchase and ongoing maintenance?

- Do you prefer heritage-inspired designs or modern engineering approaches?

By answering these questions honestly, you can narrow your focus to movements that align with your actual needs rather than marketing narratives.

The classic pilot watch aesthetic can house various movement types, from traditional manual-wind to sophisticated modern automatics. The key is selecting the movement that provides the specific functionality you’ll use most frequently.

Future Innovations: The Next Generation of Pilot Chronograph Movements

The evolution of chronograph movements continues at a rapid pace, with several key innovations poised to redefine what’s possible in pilot watch engineering. These advancements promise to enhance performance while preserving the mechanical craftsmanship that enthusiasts value.

Advanced Materials Revolution

Traditional metals are increasingly being supplemented or replaced by next-generation materials:

- Silicon components: Balance springs, escapements, and anchor wheels made from silicon offer superior performance, including complete antimagnetic properties, reduced friction, and no need for lubrication

- Carbon composites: Lightweight yet rigid carbon-based components reduce movement mass while maintaining structural integrity

- Ceramic bearings: Near-frictionless operation improves efficiency and extends service intervals

- Titanium movement plates: Reduced weight with enhanced rigidity and thermal stability

These materials address many traditional limitations of mechanical chronographs, particularly magnetic susceptibility and lubrication degradation.

Extended Power Reserve Innovations

Modern engineering is dramatically expanding power reserve capabilities:

- Multiple mainspring barrels: Providing 80-120 hours of reserve

- Optimized gear train efficiency: Reducing energy loss throughout the movement

- Low-friction escapements: Minimizing energy consumption at the regulating organ

- Variable-inertia balance wheels: Maintaining amplitude consistency throughout the power reserve cycle

These advances ensure that pilot watches remain operational during longer periods between wearing, eliminating the inconvenience of resetting after short periods of disuse.

Antimagnetic Excellence

Complete immunity to magnetic fields represents a significant advance for pilot watch movements:

- Non-ferromagnetic alloys: Replacing traditional ferrous metals throughout the movement

- Silicon escapements: Eliminating the most magnetically vulnerable components

- Movement designs that eliminate the need for protective cages: Allowing for thinner cases and display casebacks

These developments parallel similar innovations documented in the dive watch heritage evolution, where material science has continuously improved performance in specialized timepieces.

Despite technological advancements, the fundamental appeal of mechanical chronographs remains strong. The marriage of traditional watchmaking craftsmanship with modern materials and engineering represents the most exciting direction in pilot watch development, as seen across the dive watch innovation timeline.

FAQ: Essential Questions About Pilot Watch Chronograph Movements

What are the most reliable chronograph movements for aviation use?

For pure reliability, the ETA/Valjoux 7750 and its derivatives remain the benchmark for robust performance under aviation conditions. With millions produced over decades, these movements have proven exceptionally dependable. For higher-end applications, Breitling’s B01, IWC’s 69000 series, and Omega’s coaxial chronograph calibers offer excellent reliability combined with more refined engineering.

How often should mechanical chronograph movements be serviced?

Most manufacturers recommend service intervals of 5-7 years for automatic chronograph movements. However, pilots who frequently operate in high-vibration environments or extreme conditions should consider more frequent maintenance intervals of 3-5 years. Regular service ensures proper lubrication, seal integrity, and mechanical alignment—all critical for reliable chronograph operation.

What’s the difference between column wheel and cam-actuated chronographs?

Column wheel chronographs use a wheel with protruding columns to control chronograph functions, resulting in smoother operation and more precise pusher feel. Cam-actuated systems use shaped cams and levers to control the same functions, typically with a slightly firmer pusher action but greater durability. While column wheels are traditionally considered more prestigious, many professional pilots prefer cam-actuated systems for their robustness in field conditions.

Does COSC certification matter for pilot chronographs?

COSC certification provides independent verification that a movement meets strict accuracy standards (+6/-4 seconds per day). While not essential, this certification ensures consistent performance across various positions and temperatures—conditions particularly relevant to aviation use. Many pilots value this standardized testing as additional assurance of reliable timing performance.

Are high-beat movements (36,000 vph) worth the premium for pilot watches?

High-frequency movements like the Zenith El Primero offer more precise chronograph resolution (1/10th second versus 1/8th second) and potentially smoother seconds hand movement. For pilots who use chronograph functions for precise calculations, this increased resolution may justify the premium. However, these movements typically require more frequent servicing due to increased wear on components.